The Structural Tension Analysis For All Major Retaining Ring Types And Selection Smey

Explore rotor clip's comprehensive formulas and calculations for retaining rings to ensure optimal performance for your applications. Here comes the realization that you have many different ring types and options to choose. Understanding the form, fit, and function of retaining rings most engineers know the benefits of incorporating retaining rings into a design, either as a luxury to help split tolerances, as a necessity to absorb vibration, or simply to help cut costs in a manufacturing process

301 Moved Permanently

The three main types of retaining rings most commonly used are tapered section, constant section and spiral and each. You tried looking up a retaining ring based on the size of your housing or shaft diameter Allowable thrust load of retaining ring (n) a

Shape factors of retaining ring (see table 1) d

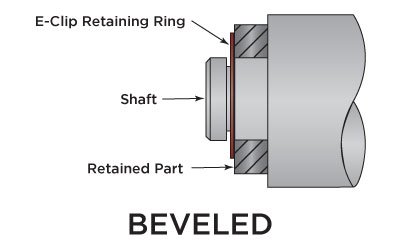

Shaft diameter or housing diameter (mm) t Plate thickness of retaining ring (mm) the beveled rings need to allow for the plate thickness when fit since they may be fit at half of the groove depth in relation to the retained work. Retaining ring design considerations reduce your fastener assembly costs by designing in a rotor clip retaining ring Consider replacing costly traditional fasteners with retaining rings and enjoy savings you didn't know were possible

Before you designate a ring for your application, follow. Understanding the load capacity of a smalley retaining ring assembly requires calculations for both ring shear and groove deformation, with the design limitation being the lesser of the two. The following pages of spiral retaining ring and snap ring engineering design have been developed from over 40 years of extensive testing and research into the various applications of retaining rings The formulas are provided for the preliminary analysis of a ring application and the design of a smalley® retaining ring.

Discover the essentials of retaining ring design calculation in this comprehensive guide

Learn sizing, material selection, and stress analysis for optimal performance. Load applied to the spring (n) e Longitudinal elastic modulus (mpa) b Gap's angle (see the above illustration) (rad) δ

Construction of a three dimensional model of the rotor body, retaining ring, and centering ring in their original configurations Ody interference fits and centrifugal loads The centrifugal loads will include all the modeled co run the model and document the nominal stresses including stationary and operating speed stresses for comparison. Restrained shoring systems derive their capacity to resist lateral loads by their structural components being restrained by tension or compression elements connected to the vertical structural members of the shoring system and, additionally, by the partial embedment (if any) of their structural components into the foundation material.

There are a few key advantages to using retaining rings over other types of fasteners including reduced machining costs, simpler product designs, and more efficient assembly

For detailed information on the different types of retaining rings offered by huyett, check out the faqs below. Study with quizlet and memorize flashcards containing terms like subsidence is the condition in which expansive soil gains moisture., in general, based on the thonrwaite moisture index and expansive clay map of central and east texas, the soil san antonio is more expansive than in bryan/college station., of the major soil types, which is has the smallest particle size A retaining wall is one of the most important types of retaining structures supporting soil masses, preventing erosion, and managing changes in ground elevation However, despite their importance, retaining walls are vulnerable to failure if not properly designed, constructed, or maintained.

The behavior of this type of walls is complex and for their analysis, simplification assumptions need to be made There are two main methods of analysis In this method, the assumption is made that the embedment depth isn't large enough and thus the lower end of the wall is free to rotate. Purpose the purpose of this manual is to provide guidance for the safe design and economical construction of sheet pile retaining walls and floodwalls

This manual does not prohibit the use of other methods of analysis that maintain the same degree of safety and economy as structures designed by the methods outlined herein.

Circular rings and arches this page provides tables of formulas for circular rings and arches from the stress analysis manual, air force flight dynamics laboratory, october 1986 Other related chapters from the air force stress analysis manual can be seen to the right. Reported by aci committee 318 preface the building code requirements for structural concrete (code) covers the materials, design, and construction of structural concrete used in buildings and where applicable in nonbuilding structures The code also covers the strength evaluation of existing concrete structures.

The retaining ring is one of the most important tools in construction It is used to secure individual components and prevent axial movement In this article, we will take a look at the different types of retaining rings, their features and their utilization. Designing a retaining wall is a complex engineering task that involves understanding soil mechanics, structural stability, and environmental impacts

Proper material selection, thorough testing, and detailed analysis of load cases—particularly earth and water pressures—are essential for safe and sustainable construction

With careful planning and execution, retaining walls not only prevent. Introduction this document has been prepared to provide guidance when designing retaining walls using elite precast concrete limited's interlocking concrete blocks It is intended to assist civil/structural engineers and architects in the best practice of designing these types of gravity retaining structure. Retaining rings are engineered components used to hold many types of assemblies together

They are precision engineered to accurately position, locate and retain parts on shafts or in bores The rings are installed into a groove, and all the other components of the assembly sit against and are retained by the ring. Since the 1970s a need for deep water structure that would exploit energy resources such as oil and natural gas has arisen Depending upon the depth of the sea water and as per the requirement, various types of platforms are designed

When deep water combines with hostile weather condition, necessary conventional fixed offshore structures require excessive physical dimensions to obtain the.

So you completed the first step by learning what a retaining ring is, as well as when and why you should use one Retaining ring overview) now you're searching by using our part tool search