It Managers Debate The Reliability Of Fan V Belts And Pulleys & Atoc Auto

In industrial ventilation systems, one of the most common questions engineers and plant managers ask is Learn about their maintenance, troubleshooting, and design options for optimal engine performance. Which is better — a direct drive fan or a belt drive fan? both designs have been widely used in manufacturing facilities, hvac systems, and exhaust setups

Simple Guide For Measuring Fan V-Belts Hog Slat, 59% OFF

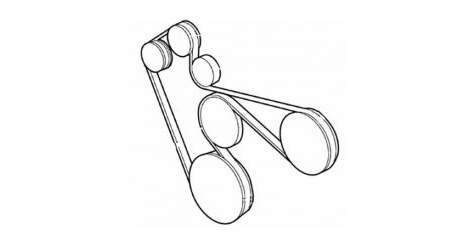

This design ensures higher efficiency and lower maintenance, making it a preferred choice for businesses seeking reliability and energy savings This article discusses the most commonly used pulleys in machinery, their advantages, and disadvantages. How fan belts and pulleys work together power transmission the engine or motor drives the fan belt, which wraps around one or more pulleys

As the motor or engine rotates, the belt moves, transferring rotational power to other components connected to the pulleys

Speed and torque adjustment the size of the pulleys determines the speed and torque ratio between the components The motor drives a small pulley which, through the belt, rotates a larger pulley connected to the fan This configuration makes it possible to adjust fan speed by changing the pulley sizes, without altering the motor speed. The equations using this friction are beyond the scope of this paper but they are based on euler's equation

The fan component of these systems is critical for the effective distribution of conditioned air Two primary fan drive systems are utilized in commercial hvac applications Belt drive and direct drive systems. This article provides an overview of the main power transmission systems used in industry including belts, chains, shafts, pipes, and electrical drives and highlights how these elements work together to.

This limit minimizes bearing loads, resulting in increased reliability

45 fanbelt maintenance practices in order to maximize the reliability of fan systems, the following practices are recommended Checking belt tension and pulley alignment periodically Belt drives should be tightened to the lowest level where the belt does not slip at. Efficiency the direct coupling of the motor and fan in direct drive systems results in higher efficiency, as there are no mechanical losses from belts and pulleys

The motor energy is transferred directly to the fan blades Belt drive fans incur some efficiency losses due to slippage and friction in the belts and pulleys. Same and next day delivery. With a groove width of 8.9±0.13, they facilitate effective power transmission and reduce slippage.

Discover the types of pulley and other mechanical devices, how to choose the right pulley, and best practices for maintenance.

Re based on euler's equation Kristian campbell is industrial sales manager for dayco products llc. Pulleys are essential components in mechanical power transmission systems, used to transfer motion and torque between rotating shafts via belts Different types of pulleys are designed to match specific belt types and operational requirements