The Polyurethane And Steel Tension Cord In Gates Timing Belts Onle Product Catalog Timg Pfeifer Dustries

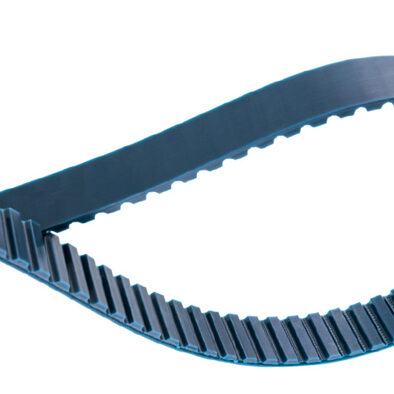

Nearly every extruded belt type can be additionally customized by adding coatings and profiles or special machining. Certain vehicle engines require specific belt constructions, such as aramid tensile cord, to provide long belt life, and eliminate noise and vibration that are inherent on these drives. Why a synchronous belt in automotive engines

Timing Belts: Synchronous Belts, Polyflex Belt, Gates Timing - Ajay

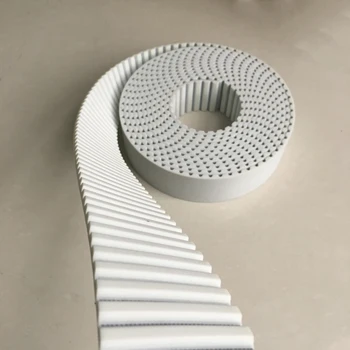

Synchronous belt drive systems, used to synchronize cam and crank shafts, replaced the classical chain drives when overhead camshafts were the first belt was made of polyurethane with steel cord tension members Exhibits an increased chemical resistance, compared to rubber, and can be welded as a thermoplastic material. The belt teeth of polyurethane serve for the force transmission between the tension cord and the tooth fl ank of the timing belt pulleys, whereas the polyurethane webs, depending on the profi le, support the tension cords against the tooth crests of the pulley, see e.g

T profi le in fig

Timing belt backings does your application demand polyurethane belts tailored for specific performance needs Nearly every extruded belt type can be customised by adding coatings, profiles or special machining 1 / body the body of the belts are grey/green thermoset polyurethane 88 sha The thermoset polyurethane is obtained by mixing a prepolymer with a bonding compound and heating the mixture

2 / cord high strength helically wound zinc coated steel tension members allow high breaking load and extremely low elongation available with kevlar, fiberglass, stainless steel, hp, hf, hpf cord. Our truly endless flex belts are extruded belts with helically wound steel cords designed for high flexibility with all gates tpu backing and profile options. Same and next day delivery. Megaflex timing belts are manufactured in thermoplastic polyurethane, with continuous spiral steel cords

This type of belt, developed by our research & development, offers good running characteristics and high traction loads.

The curvilinear profile enables the belts to establish a broader contact surface with the pulley, enhancing overall performance. In 1946, gates invented the first toothed timing belt, known as the synchronous belt Timing/synchronous belts many systems use timing/synchronous belts to modify speeds and relay the torque that powers equipment from electric motors or other drives to the driven equipment These belts require proper alignment to optimize the belted drive's longevity, offering the benefits of safety and efficiency in your system

The timing belts are available in neoprene (rubber) and pu (polyurethane) and can be selected with a tension cord made of glass fibre, aramid fibre (kevlar), stainless steel, carbon fibre or steel. Consisting of both conveyor belts and timing belts suited for use in direct or proximate food contact applications, our products offer a range of industry leading features including Sealed, embedded tension cords to. Having no splice or welding, the belts.