Ensuring Long-term Calibration Accuracy In Aerospace Using 13/16 To Mm Values Accurate & Repair Service

This nasa technical standard establishes technical requirements to ensure the accuracy of measurements affecting safety and mission success through the proper selection, calibration, and use of measuring and test equipment (mte). C., easily meeting the gage r&r 10:1 rule. The future of precision in aerospace as technology continues to advance, the need for precision in aerospace manufacturing will only increase

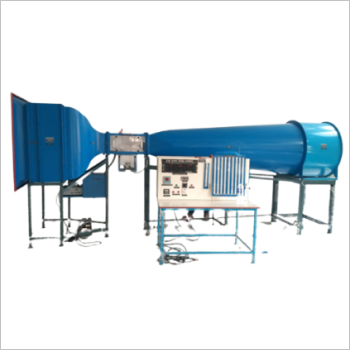

Infrastructure Hydroment Calibration Facility | Azista Aerospace

Future developments in aerospace will likely demand even tighter tolerances and more rigorous standards, making reliable measurement instruments like mitutoyo indicators more important than ever. Involves calibration of automotive testing equipment to ensure vehicles meet emission and safety standards. Precision calibration services for aerospace and defense the aerospace and defense industries operate at the pinnacle of precision engineering, where measurement accuracy can determine mission success, flight safety, and national security

Every component, system, and assembly must meet exacting standards that leave no room for measurement uncertainty or calibration errors

Calibration is the process of comparing measurement instruments against a known standard to ensure accuracy In aerospace, this means ensuring that every tool, gauge, and measurement device. Explore calibration of measurement instruments in aviation & aerospace component manufacturing for quality control insights. Calibrationhouse provides expert calibration services to aerospace manufacturers, maintenance providers, and testing facilities

By ensuring precision across critical instruments, calibrationhouse helps aerospace companies maintain compliance with industry standards and ensure operational safety. Calibration is an integral part of those measurement controls and is vital to ensuring the continued adequacy of mte for its intended use The metrology and calibration program also collaborates with industry and other government agencies in the development of metrology and calibration standards, guidance documents and best practices. Our commitment to excellence in aerospace equipment calibration and inspection ensures that your business aviation operations remain at the forefront of industry standards

With meticulous attention to detail and a dedication to best practices, our calibration solutions guarantee the accuracy and compliance your aircraft demands.

See how calibration in aerospace & defense is shifting from paper systems to digital traceability, predictive analytics, and globally auditable data integrity. At eml calibration, we understand the paramount importance of calibration in ensuring reliable and accurate measurements and avoiding inaccuracies But why is calibration necessary? Cmms are essential for complex, 3d measurements of intricate components

These machines use probes to measure the geometry of objects, making them critical for industries like aerospace and automotive. Calibration in measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. To calibrate testing equipment is to level gear so measurements remain accurate and consistent Calibration keeps results honest and trustworthy, which counts

In this article, we will discuss the basics of calibration, its importance, the different methods used for calibration, and the latest developments

What is meant by calibration Calibration is the process of comparing a measurement device or system's accuracy to a standard. Learn the fundamentals of calibration, its importance in measurement accuracy, and how fluke calibration supports precision across various industries. Ensuring a 4:1 ratio will minimize the effect of the accuracy of the standard on the overall calibration accuracy

If a higher level standard is found to be out of tolerance by a factor of two, for example, the calibrations performed using that standard are less likely to be compromised. To maintain measurement accuracy, system reliability, and compliance, regular calibration is essential This guide explains what sensor calibration is, why it matters, and how to build a calibration strategy that keeps your instrumentation sharp and dependable. Calibration is the act of confirming that a method or system, or instrument used in measurement will produce correct results

There are two standard calibration procedures

These methods or systems require one or more standards of known composition to calibrate the measurement Traceability means the result of a measurement can be related to a reference through a series of calibration reports The jmr pd drift compared to ground truth over the four years since the launch was reduced from 3.9 to −0.01 mm/year with the recalibrated nd time series. Focuses on the instruments used in aerospace for navigation, which require extremely high accuracy levels automotive calibration