The Geometric Efficiency Explained For A Specialized Pulley For Belt Chin V Mnufcturers Suppliers Fctory Custom V

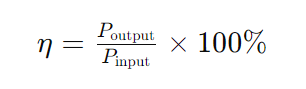

Invented by john gates in 1917, their easier tracking on pulleys and higher friction (which we'll explain more on a moment) also allow high force transmission even at relatively low tension values Whether you're puzzled by how to calculate the correct pulley diameter or curious about the factors influencing belt and pulley selection, this guide will provide the answers. The efficiency of a pulley system is defined as the ratio of the output power to the input power, often represented by the symbol η (eta)

Pulley Efficiency Calculator - Calculator Doc

In this article, we will explore the theoretical framework that underlies pulley efficiency, using mathematical formulas to describe the various losses that affect their performance. We'll also explore how to match belt and pulley pitch series and calculate effective belt length and center distance Calculate belts power transmission and efficiency the torque available at the driven wheel or pulley (a) can be expressed as

Calculation for 2 or 3 pulleys

Automatic design of a transmission with the minimum of input requirements Design and calculation of geometrical parameters (diameters of pulleys, axis distances, length of the belt, weight of the transmission) calculation of strength parameters (power transferred by the belt, number of belts, efficiency, etc.) calculation of force conditions (prestressing, axis. Yes, the efficiency of a belt pulley system can be improved by reducing friction, increasing belt tension, and using larger pulleys How important is proper maintenance in ensuring the efficiency of belt pulley systems

Proper maintenance is essential in ensuring the efficiency of belt pulley systems. Belt rubber shear, normal, axial and lateral stresses Belt slip is measured using the. Discover advanced techniques for designing and optimizing pulleys and belt drives, including simulation, analysis, and testing methods.

Glazing reduces the friction even further, decreasing drive eficiency

Other noticeable signs include the belt and pulley both being hot to the touch — especially the pulley. The efficiency of a pulley system is influenced by several factors, including friction, belt or rope wear, misalignment, and load variation Understanding these factors is essential for designing and optimizing pulley systems. Guide design guide on pulleys and belt drives efficiency and reliability are paramount in an industrial environment

Whether you're lifting loads, applying forces, or transmitting power, the right belt and pulley system can make all the difference. A pulley is a simple machine that is used to transfer force and motion It consists of a wheel with a grooved rim that holds a rope or belt When force is applied to one end of the rope or belt, it causes the wheel to rotate, transferring the force to another object

Understanding the various parts of a pulley is essential for its proper operation

A typical pulley has several key components. Conclusion in summary, both sheaves and pulleys play vital roles in mechanical systems that require the movement of heavy loads Sheaves, pronounced shiv, are specialized components that guide and support ropes or cables, enhancing efficiency and reducing the effort needed for lifting and moving. If you do not have an indico account yet, you can create one here.

Pulleys, blocks and tackles.block, tackle or pulley calculator the calculator below can be used to calculate effort force in block, tackle or pulley construction The calculator can be used for metric and imperial units as long as the use of units are consistent Belts and pulleys are often used to transmit motion and torque. Pulley systems are widely used in various mechanical applications to transmit power or motion from one point to another

One of the critical parameters in designing an efficient pulley system is calculating the exact belt length, which affects the overall performance and lifespan of the system

In this article, we present a theoretical model for calculating the exact belt length based on the. Discover how pulleys revolutionized engineering—from ancient monuments to modern machines Learn the theory, history, and practical uses of fixed, movable, and compound pulley systems in this comprehensive guide. The speed ratio gets the operational speed of the equipment and defines the geometric shape and size envelope of the drive system.

The manufacturing process for aluminum timing belt pulleys typically involves several key steps:material preparation First, suitable materials, such as aluminum alloys or other metals like cast iron, copper, or stainless steel, are selected based on the pulley's requirements for hardness, strength, and other characteristics The geometric shape and dimensions of the. The efficiency of a pulley system also depends on the friction between the rope or cable and the pulley

Friction reduces the mechanical advantage of the pulley system by absorbing some of the force applied to the rope and converting it into heat.

Discover the types of pulley and other mechanical devices, how to choose the right pulley, and best practices for maintenance. Pulleys transmit power and motion, either individually or in combination Sheaves are pulleys with grooved edges In belt drives, pulleys are attached to shafts at their axles, and power is transferred between the shafts by endless belts that run over the pulleys

Please read on as we discuss some of the different types of pulleys. Pulleys and belts are composed of two circular discs (pulleys) mounted on parallel shafts and connected by a flexible band (belt) that runs over them The pulleys can have the same or different diameters, which determines the speed ratio between the shafts.