The Precision Hobbing And Shaping Done By The Linn Gear Company Jinwang Hardware

Our gear cutting capabilities are very diverse, including all of the most common gear types used in industry Creed monarch's complete range of cnc production solutions includes precision gear cutting / hobbing services We have machines for hobbing, shaping, generating, grinding and other finishing at our plant.

Precision gear hobbing machining - All industrial manufacturers

These include splines, notched, keyed, helical, and involute splines While hobbing works well for many materials, it may struggle with harder materials without specialized tooling. Special technologies such as hobbing, peeling, turning, or shaping are used

All processes can be integrated into our universal machining and production centers to save additional specific individual machines exclusively for gear production.

Ever wondered how gears are made The process involves multiple intricate steps to achieve precision and efficiency This article breaks down the 11 essential stages of gear processing, from ordinary turning to final measurement By the end, you'll understand the critical role of.

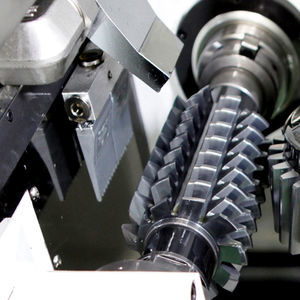

The image shows a gear shaping or hobbing machine, where the operator is adjusting the cutting mechanism and alignment to achieve accurate gear geometry Hobbing is regularly used to produce spur, helical, and worm gears—as well as splines—in materials ranging from carbon steel, stainless steel, and nonferrous metals The versatility and simplicity of hobbing makes it an efficient and economical method of cutting gears and splines, compared to other gear forming processes. Both gear hobbing and gear shaping find widespread use in industries requiring precision gears for power transmission, motion control, and mechanical systems

Some common applications include automotive transmissions, aerospace propulsion systems, industrial machinery, and precision gearboxes.

With the right tools and materials, and careful attention to the hobbing process, manufacturers can create gears that meet the precise specifications required for various industrial applications. Hobbing is suitable for mass production of cylindrical gears, with high processing efficiency and good consistency of tooth shape Gear shaping gear shaping, the use of shaping a knife (shaper), can process external or internal teeth, is in addition to hobbing commonly used method of spreading tooth cutting process. Achieving precision through finishing after the initial tooth profile is cut, the resulting gear is often subjected to heat treatment to increase its hardness and wear resistance.

And we have 40+ years of expertise in gear and spline cutting and all of the machining that goes with it. With a variety of machining options including hobbing, shaping and broaching, precision gears, inc Can meet or exceed your specific custom gear manufacturing requirements Our facility also has advanced gear inspection equipment, ensuring quality from start to finish.

Gear grinding & polishing gear honing internal gear hard skiving gear broaching gear hobbing & shaping nvh gear analysis & testing do you need a custom precision gear manufacturer

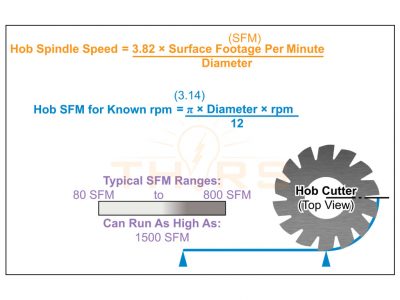

Discover precision gears, inc., a leader in gear hobbing services Offering custom solutions & advanced inspection for quality assurance In summary, gear hobbing is a versatile process suitable for a wide range of gear types and sizes, providing good tooth profile accuracy and efficiency Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing ratio between hob and gear blank.

We have machines for hobbing, shaping, generating, grinding and other finishing at our plant Our inventory of gear cutting tools is extensive, covering a broad range of common and uncommon diametral (both normal and transverse), circular, agma & fellows stub and metric pitches. Cnc gear processes are commonly used in various industries where precise gears are required, such as automotive, aerospace, robotics, and industrial machinery manufacturing. This makes it an essential method for applications requiring intricate designs or precise specifications.

How it actually works (detailed explanation) gear shaping is one of the most versatile gear manufacturing processes used to cut internal and external gears, spur gears, helical gears, and even shoulder gears where other methods fail

The magic of gear shaping is simple A cutter shaped like a gear cuts another gear while both rotate together. Hobbing often results in superior gear precision and surface finish compared to shaping