The Fluid Dynamics Science Required For Modern Shaft Sealing What Is ? Live

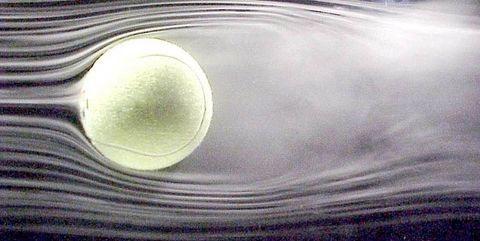

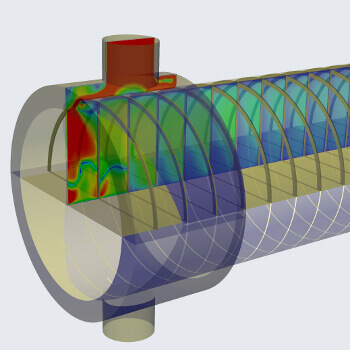

While these effects have traditionally been investigated through experimentation, this study introduces a numerical approach to analyse the impact of the shaft counterface on the lubrication and sealing mechanisms of rotary shaft seals. [16] investigate the fluid flow of a ribbed sealing lip in contact with a shaft using computational fluid dynamics (cfd) simulations Abstract the primary task of rotary shaft seals is to prevent an unwanted fluid transfer between two areas

Computational Fluid Dynamics Engineering Consulting Services • Dynaflow

In shaft passages of gearboxes, for example, rotary shaft seals avoid the leakage of transmission oil to ambient air. Engineered for durability, low friction, and superior sealing performance. The lubricant flow in the sealing gap significantly affects the sealing behavior of rotary shaft seals

Computational fluid dynamics (cfd) are applied here to analyze these fluid flows.

The primary task of rotary shaft seals is to prevent an unwanted fluid transfer between two areas In addition, a research methodology was developed to systematically analyze the fluid flow and the distortion of the sealing surface of shaft seals The results of the test procedure are documented in an evaluation matrix that allows the comparison of sealing systems with different worn sealing edges. In order to vary the dynamic eccentricity, shaft adapters were used, which take up the shaft sleeves eccentrically to the axis of rotation.

This tutorial is aimed at industrial or academic workers interested in rotating machines including dynamic shaft seals Training can be either a first contact with problems of seals lubrication or an updating of previous knowledge This paper reviews the current state of dynamic sealing technologies, examining the challenges faced by conventional sealing methods under complex working conditions, such as high temperature, high pressure, and corrosive environments. This guide delves into the types, materials, and applications of shaft seals, providing valuable insights for engineers and industry professionals

Readers can expect to learn about the different designs of shaft seals, including lip seals and mechanical seals, and their specific uses in various industries.

Heat transfer, fluid dynamics, mechanical vibration and the chemistry of elastic materials all interact to prevent the leakage of fluid The components, when correctly chosen, are able to function in a. These mechanical seal arrangements offer enhanced sealing performance by incorporating two mechanical seals in a single housing, separated by a barrier fluid This configuration minimizes the risk of process leakage reaching the atmosphere, ensuring compliance with regulatory emissions requirements while maintaining operational eficiency.

The use of finite element analysis (fea) and computational fluid dynamics (cfd) to predict the performance of mechanical seals has become well establi… Learn about the 7 types of dynamic seals commonly used in mechanical design and manufacturing, and their applications in various industries Boost your engineering knowledge today! Introduction mechanical seals and mechanical seal technology have come a long way, from the earliest application as part of the cooling system in the legendary ford model t to the high performance sealing tasks in modern turbo gas compressors.

Through the designed visual mfs device experimental bench, the magnetic fluid seal pressure curve and magnetic fluid motion state are monitored in real time to reveal the intrinsic connection between the two and further explain the mechanism of life shortening of magnetic fluid in dynamic and static sealing state

It provides a certain reference for the design and application of magnetic fluid. This comprehensive approach ensures that the seals not only meet but exceed the operational demands of modern hydroelectric power generation, marking a significant step forward in the field of mechanical engineering and fluid dynamics. How labyrinth seals work is a subject that blends fluid dynamics, thermodynamics, and smart mechanical design Requirements such as high opening force, low leakage rate, and design without matching auxiliary flushing systems are expected of the modern fluid machinery shaft seals used in the process industry

Overview of our dynamic sealing solutions radial shaft seals explore freudenberg sealing technologies' simmerring® radial shaft seals, oil seals, and rotary lip seals for industrial and automotive applications