Roboticists Debate The Backlash Tolerances Of New Speed Reducers Zero Onvio Pdf Catalogs Technical

Finally, the dtes of the new reducers with three different tolerance designs are analyzed numerically and tested experimentally The show closed with a debate between six leading roboticists: The results show that the new reducer with a reasonable tolerance design can achieve high transmission accuracy and has the potential for application in the joints of industrial robots.

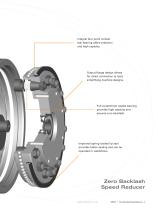

Zero Backlash Speed Reducers - ONVIO - PDF Catalogs | Technical

Precision reducers account for about 25% of the material cost of industrial robots, which determines the important performance indicators of industrial robots [1] A group of roboticists from around the world investigated this divide at the ieee international conference on robotics and automation (icra) earlier this year Precision planetary reducers provide driving power to the wheels

Planetary reducers ensure precise linear velocity control by accurately regulating the speed of the drive wheels, enabling the robot to travel smoothly along the path and speed planned by the navigation system.

Throughout the debate, panelists emphasized the diversity of the robotics field itself While deep learning has transformed perception and language tasks, robotics involves a multiplicity of challenges As mentioned earlier, manufacturing tolerances can have a significant impact on backlash By using precision manufacturing techniques, such as cnc machining and grinding, we can ensure that the gears and other components in our reducers have tight tolerances

This helps to minimize the clearance between the mating parts and reduce backlash. The homemade reducer has obvious backlash problems due to assembly tolerances, machining tolerances, etc., so the actual backlash of the current reducer is measured. These speed reducers are known for their low or even zero backlash, but how do these claims hold up, especially in the long run Precision planetary drives are known for their high torque and precision

Efficiency, backlash, to rsion al stiffness, noise, and assembly

The problem of precision reducer is analyzed, and finally the application and development trend o f reducer are studied. Speed reducers—also known as gear reducers or gearboxes—are mechanical devices designed to decrease the rotational speed of an input shaft while proportionally increasing the torque at the output shaft Archimedes drive is a traction drive based speed reducer, also known as a drive or gearbox without gears Built around a simplified & scalable design, it delivers high torque in a compact and robust form factor.

Nema 23 gearbox body length Gear reduction box backlash precision <= 12 arcmin, full load efficiency 96%, max input speed:8000rpm, rated input speed

There are few basic ways to reduce or optimize backlash

Precision gears and modified gears Precision gears variables such as manufacturing errors, mounting tolerances, and bearing play often increase the amount of backlash in a speed reducer By designing gears with intentional clearance, engineers can accommodate these small inaccuracies, ensuring gears mesh without interference. Research on cycloidal gear reducers dates back to the studies of botsiber and kingston [1] and pollitt [2], where the cycloidal speed reducer was initially introduced

Blanche and yang [3] used a vector method to generate the cycloidal profile and then analyzed the machining tolerances and their influence on output speed. A zero backlash gearbox allows to amplify torque output of a motor without impairing its design performance Lash minimization can involve structural modifications or using a specific gearing technology or arrangement Read on to learn more.

Thanks to a kit module design, that makes them available for all speed reducer ranges, these reducers are easy to set up

They are available in 4 sizes. Matbet güncel giriş ve matbet giriş adreslerine tek sayfadan ulaş Güvenli yönlendirme linkleri, giriş butonları ve matbet hakkında bilmen gerekenler burada. Our technology first new practical speed reducer in the last 50 yearsdiscover

It has been commonly used for transmitting motion and torque in machinery The topological structure of cycloidal drives is discussed and analyzed with the aid of graphs New cycloidal gear reducers are.