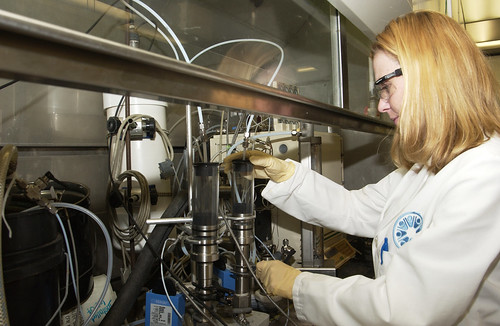

The Engineering Strategy Behind The Sumitomo Gearbox Design รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

Industry recognition our approach to material selection has caught the attention of the engineering community Our engineers will be able to craft a custom solution to match your design specifications if none of our stock products fit your needs. Machine design, a leading industry publication, recently featured sumitomo drive technologies in an article on materials selection for mechanical components

Engineering Gears Sign Business Free Stock Photo - Public Domain Pictures

The article highlighted how our commitment to using stronger, more durable materials results in gearboxes that are both lighter. All of our premier products are available from our manufacturing facilities in virginia, illinois and texas Explore the technology behind the invention cycloidal discs have a wave shaped rotation around a stationery ring gear housing

The lobes of the discs engage with the pins of the ring gear housing, which then rotate at a reduced speed

The reduction ratio is determined by the number of cycloidal lobes on the cycloidal disc This rolling motion creates a gear that can effectively share the load. The retractable roof is driven by 96 sumitomo gearboxes After over 24 years of service, a sumitomo gearbox was returned for overhaul

The gearbox's condition is a testament to the importance of. Information on large gearboxes from sumitomo heavy industries What is a sumitomo cycloidal gearbox Sumitomo cycloidal gearbox is a type of gearbox that is known for its unique design and functionality

It is a mechanism that offers superior performance in terms of load capacity, impact resistance, and efficiency.

What began in europe in 1925 with the company's own. They are greatly utilized in different programs, like robotics, industrial equipment, conveyors, and substance managing gear The style and design of sumitomo cycloidal gearboxes incorporates sophisticated engineering and supplies to assure efficient electric power transmission and trusted effectiveness. From their inception in japan to becoming a staple of industrial machinery across the globe, sumitomo gear motors embody a tradition of innovation and excellence

They stand as testament to the power of combining engineering expertise with advanced technology to meet and exceed modern industry demands. Sumitomo drive technologies, a division of sumitomo heavy industries, is a globally recognized manufacturer of premium gearmotors and power transmission systems With over 100 years of engineering heritage, sumitomo gearbox are known for exceptional reliability, advanced torque control, and long service life—especially Solutions the sumitomo cyclo reducer is unique in the use of the eccentric cam and cyclo disc arrangement

This revolutionary design provides quiet, efficient, and reliable performance exceeding that of involute tooth gear designs

The facility selected for this case study has a very large installed base of sumitomo cyclo products. Kisssoft 2025 available in april the new kisssoft release brings innovations and enhancements for results visualization, allowing you to design even more efficiently, precisely, and productively Sumitomo drive technologies usa delivers gearmotors, reducers, vfds, and full power transmission solutions designed for industrial operations around the world. With over 100 years of experience in the industry, sumitomo is a trusted manufacturer of gearmotors, offering a range of gearbox solutions suitable for a wide range of industrial applications

Regularly review maintenance records to identify patterns or recurring issues that may indicate a need for changes in maintenance strategies or equipment design. Gears deliver force (torque) and motion (rpm) from one part of a machine to another Being able to control speed and torque by varying the number of teeth of one gear with respect to another makes gears a valuable design. Being able to control speed and torque by varying the number of teeth in one gear with respect to another makes gears a valuable design tool.

This webinar covers how to design gearboxes (gear drives) that last longer & perform better

From application factors & gear type selection to calculations & agma ratings. You can also find and create cad drawings and product specs, customize any sumitomo product, and more If you need to request specific cad drawings, we can help with that here. Welcome to the official website of sumitomo corporation, a leading integrated trading company engaged in diverse businesses based on its global network.

This design allows for higher torque capacity and a wider range of gear ratios than concentric gearboxes, making them suitable for applications that require higher torque and speed capabilities. In this paper, two stage reduction helical gearbox has been designed The gears and shaft design calculations are done with the help of kisssoft Kisssoft is a program for machine design calculations

Kisssoft have been incorporated with various calculation methods for the gear and shaft design separately.

To power your operation, sumitomo provides a comprehensive lineup of products with the gear ratios, torque, and horsepower you need