Pump Techs Debate The Spider Material Inside New Jaw Couplings & Ppt

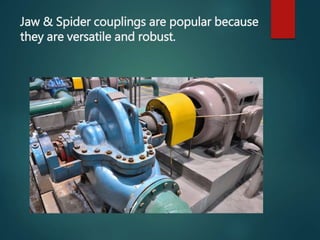

Spiders are key to jaw coupling performance one of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling Jaw couplings are popular because they are versatile & robust This design is characterised by two hubs, each having two or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub.

Jaw & Spider Couplings | PPT

The spider is the key determinant of the torque rating of each jaw coupling Two identical hubs with 3 face lugs are connected through a star shaped element, sometimes referred to as an insert or spider. It also can make a significant difference in the coupling's response to vibration, temperature, chemicals, misalignment, high rpm, space limitations and ease of installation or removal.

Selecting the right type of spider is just as important as selecting the right type and size coupling

For that reason, users will benefit from a fuller understanding of the different spider constructions and materials available, when specifying new or maintaining existing couplings Find the best coupling spider for your application with this guide covering materials, performance, torque ratings, and maintenance selection tips. The heart of the system Decoding the spider (insert) material science & selection

Hardness, durability and torque the material properties of the spider, which is the fuse in the mechanical circuit, are the key determinants of the performance of a jaw coupling Engineers have to balance between damping and torque transmission. Explore the intricate world of jaw couplings and uncover the significance of rubber spider for jaw coupling in this comprehensive guide Learn about the composition, functionality, advantages, and maintenance of rubber spiders, as well as considerations for selecting the right one for your application

Discover why rubber spiders stand out in vibration dampening, misalignment compensation, and.

An essential component of jaw couplings, flexible elastomeric spiders transmit torque and accept misalignment Design and material options for these flexible elements let you. Elastomer jaw couplings have been around for 100 years or more Most of these couplings use two hubs and an elastomeric spider between the jaws to transmit torque.

A rubber spider is a flexible nylon insert used in certain types of couplings, most commonly jaw couplings Think of it as the crucial cushion or shock absorber that sits between the two metal hubs (jaws) of the coupling Its primary job is to transmit torque between the driving and driven shafts while accommodating minor misalignments and damping vibrations The health of the spider directly affects the coupling's performance and the machinery's overall efficiency.

We manufacture multiple styles of jaw couplings

Their face design features a straight cut jaw shape While we have a wide variety of stainless steel ss type jaw couplings, the al and l type jaw couplings are the most popular types we stock following your selection of the jaw coupling hub type and bore size, maxtran can help you choose the appropriate spider insert material and type. The intent of this article is to familiarize you with jaw couplers, be able to calculate the torque and service factors and finally be able to select the jaw size and spider materials right for your application. We carry a wide variety of spider couplings, including jaw coupling spiders, in a range of sizes and materials

Whether you need a spider coupling for a small application or a large one, we have the right option for you. Jaw couplings connect the shaft of a motor, or moveable machine to the shaft on a stationary machine Expert guide to spider coupling rubber from manglam engineers Learn about materials, applications, maintenance & how to choose the right coupling for your needs.

Expert tips for selection & maintenance.

Filter jaw and spider couplings by bore size (inches/metric), od & durometer to modify or request a quote Berg precision spider bearings are made in the usa. Rubber spider couplings rubber and polyurethane spiders are an essential component of jaw couplings a jaw coupling is a power transmission coupling that can also be used in motion control applications, for example, a motor It connects two shafts while minimizing vibrations and compensating for any parallel, angular, and axial misalignment.

Choose from our selection of lovejoy couplings, including set screw flexible shaft couplings, clamping flexible shaft couplings, and more Same and next day delivery. Jaw couplings are one of the first and still most widely used elastomer couplings in the world due to their inherent simplicity