Mounted Bearings: The 2026 Solution For Remote Mining Sensors Use Of Rmal In Pptx Geology Science

Additional accessories, from adapters to installation tools, are available to allow for installing optify solutions on your mounted bearings, gear reducers, and motors—expanding your application capabilities Patented features offer a consistent performance. The mining industry faces unique challenges in remote areas where traditional connectivity fails

TIMKEN Bearings vs. SKF Bearings: Who Performs Better in the Mining

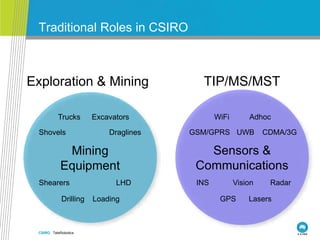

What is remote monitoring in iot When combined with diagnostic electronics, accelerometers enable comprehensive vibration monitoring of large drives. Legacy monitoring solutions lack the networked, remote controlled functionality of iot in the mining industry

Meanwhile, remote monitoring allows mining companies to continuously track key factors in their operations, such as the equipment health, resource extraction and worker safety.

With the rising demand for critical minerals comes a heightened need for more mining and even more efficient mining solutions These innovations enable remote monitoring and control of operations, optimize production schedules, and minimize downtimes Moreover, the use of intelligent technologies in drilling, excavation, and maintenance enhances precision and reduces the likelihood of human errors. Smart sensors can help address some of the performance issues and safety challenges associated with mounted bearings.

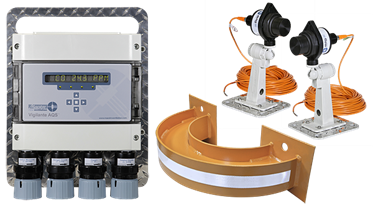

These systems are optimized for mining applications and provide remote monitoring capabilities for hard to reach locations with wireless, low power sensors The optify performance sensor unlocks your operation's potential, even in the most extreme conditions, by remotely monitoring the condition of your mounted bearings, gear reducers, and motors. Involve us at an early stage to find the right solution for your specific application Avoid unwanted failure or dust or gas explosions.

Save time and ensure safety with safety mount spherical roller bearings

Install and remove up to four times faster than the competition. Usd 10.24 billion · forecast. Usd 2.45 billion · forecast. Next level bearing monitoring and maintenance bearing clearance monitoring (bcm) for mining excavators

For the operation and maintenance of excavators, bcm offers the technologically leading digital bearing monitoring solution It provides for maximum safety and efficiency saving 75% or more of the costs per measurement. Contribute to looktooz/rimeconfig development by creating an account on github. Usd 9.4 billion · forecast.

Explore types and selection criteria for mounted bearings to enhance machinery efficiency and reliability.

Traffic light system motor health is displayed with a traffic light icon to quickly show users the state of that motor Bearing condition ultrasonic acoustic sensors to accurately assess bearing condition Vibration transmitters and sensors detect damaged bearings, unbalance in drives, and rotating machine parts