The Viral Engineering Controversy: Vee Belt And Pulley Alignment Best Practices Dotline Laser® V Tool Ludeca 49% Off

Proper alignment ensures smooth power transmission, longer belt life, and optimal machine performance Learn how to choose the right one! To determine how much misalignment is acceptable and at what point it becomes excessive, the alignment must first be measured, quantified, and then compared to the belt manufacturer's recommendations for the particular type of belt

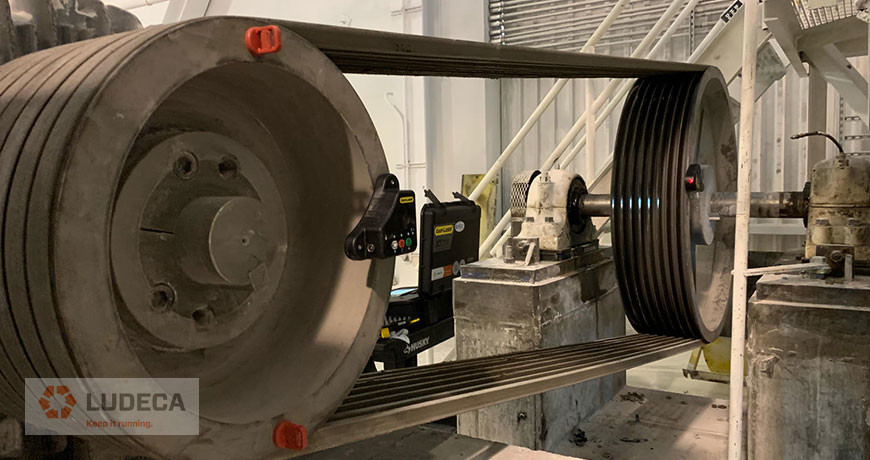

EASY-LASER® D92 BELT PULLEY ALIGNMENT TOOL - Ludeca

These recommendations can be found in drive design manuals. In machine maintenance and reliability, understanding the criticality of proper belt alignment is essential However, misalignment can introduce significant losses due to increased friction and reduced contact between the belt and pulleys.

This comprehensive guide details the importance of belt alignment in various industrial applications, focusing on how advanced strategies like laser belt alignment and laser pulley alignment have revolutionized maintenance practices.

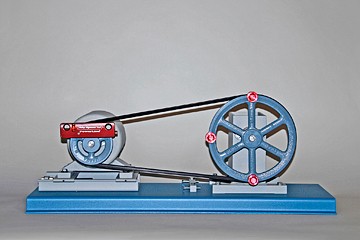

Proper alignment of pulleys ensures that belts run smoothly, reducing wear and tear on equipment components and minimizing the risk of costly breakdowns In this article, we'll explore the importance of accurate pulley alignment and how it can prevent equipment failures. The single biggest factor that can impact the reliability of belt driven equipment is pulley alignment Just a few minutes of intentional pulley alignment can lead to extended service life.

It is now the basic belt for power transmission They provide the best combination of traction, speed of movement, load of the bearings, and long service life. Setting the belt tension is readily achieved by jacking the pulleys apart and measuring the transverse distance the belt can move Higher shaft torsional loads are handled by using multiple belt pulleys

A jockey pulley can be installed to increase the angle of contact and allow transfer of more power.

The number and variety of available belt types is a testament to this Take the right steps to ensure proper drive belt alignment misalignment is one of the most common causes of premature belt failure Depending on its severity, misalignment can gradually reduce belt performance by increasing wear and fatigue Or, it can destroy a belt in a matter of hours or days.

Pulley misalignment can increase wear on pulleys and belts as well as increasing the noise and vibration levels, which can result in unplanned machinery downtime Another side effect of increased vibration is premature bearing failure. What are vee belt pulleys This design ensures a secure grip.

3d animation of belt pulley alignment in autodesk inventor @solidorbit95 #shorts #viral #youtubeshorts #animation #trending

Belt, chain & pulley alignment a common misunderstanding is that belt drives are not affected dramatically by misalignment This assumption has cost the industry a huge amount in unnecessary replacement of sheaves/pulleys, sprockets, belts and chains etc Also several investigations have shown savings up to 10 % in energy costs alone! V pulleys are an essential component in power transmission systems, and proper maintenance is critical to ensure optimal performance and longevity.

Tension the belts until the force required for this deflection equals the belt manufacturer's maximum recommended force values for the specific belts you are using. Master the art of pulley alignment with our comprehensive guide, ensuring smooth operations, extended equipment life, and peak performance. Sheaves and sprockets should be checked for proper alignment A laser alignment tool is the recommended means

Most major belt manufacturers recommend a nominal tolerance of 0.5 degrees

However, better alignment tolerances should be achieved if possible The table below can be used to determine proper alignment. Belt alignment, like belt tension, is critical Improper alignment of the motor pulley to the roll pulley (s) can result in reduced horsepower transfer, belt failure, and/or motor failure.