Keyway Dimensions: The 2026 Guide To Precise Shaft Machining Din 6885 3 Key Hub Details And Dimensions

Shaft key and keyway work together to create a robust interlocking mechanism Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul. How to design an accurate keyway

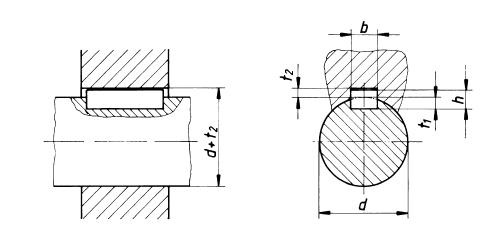

DIN 6885-3 :- Key, Hub Keyway, Shaft Keyway Details and Dimensions

This guide provides a comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design Note that they vary between coupling types What are keys and keyways in engineering, and how do they work

In mechanical engineering, a key is a crucial machine element that connects a.

Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. Keyway widths usually fall between 4 mm and 45 mm depending on the shaft's size What is keyway machining keyway machining refers to the process of making these exact grooves in hubs or shafts For this, manufacturers use special techniques such as broaching, milling and electrical discharge machining (edm).

When working with shafts, gears, pulleys, or couplings, one small feature plays a huge role in transmitting torque effectively — the keyway Whether you are in mechanical engineering, manufacturing, or repair work, knowing the correct keyway size chart is essential for ensuring proper fits, safety, and durability of mechanical assemblies. The document provides specifications for keyway dimensions for both inch and metric systems It lists nominal shaft diameters and the corresponding bottom of keyway to bottom of shaft, keyway width, and reference depth dimensions in either fractional inches or millimeters depending on the system

This page provides a detailed keyway chart to help engineers select precise seal fits for transmission applications in industrial environments.

Key dimensions the inch and metric dimensions here correspond to common values Detailed width tolerance information is best drawn from the manufacturer Diameter that use rectangular keys can be milled flat along their length instead of machining a keyslot The mounted component uses a standard broached keyway.

In this calculation, a connection with a prismatic key with a length l, height h and width b mounted on a shaft with a diameter d in a keyway with a depth t is considered The shaft is under the action of torque t As a result of calculations, shear stress τ and crushing stress σcr in the key are determined. Misumi malaysia shop for configurable components, factory automation, mechanical, electrical part, press, mold and injection

Free shipping and cad download.

Standard metric shaft key and keyway dimensions chart in mm the key dimensions listed in the following table refer to nominal size, which provides a standardized reference for selecting and specifying keys to ensure compatibility between components from different manufacturers. Custom shaft manufacturing requires a combination of expertise, precision, and high accuracy to machine shafts with tighter tolerances and complex features Complete guide to shaft keys covering the motor key types, dimension formulas, strength calculations, material selection, and practical case studies for reliable torque transmission. These keyways are defined by specific dimensions that are measured in millimeters, allowing for precise alignment and fit within mechanical assemblies

Metric keyways follow iso 773 standard, which lays out the specifications for keyways in different applications. Keyway sizes keys and keyways are used to transfer torque from shafts to holes or vise versa As a general rule, the key is a tighter fit to the shaft so that the key remains on the shaft during assembly and removal. 50 represent the basic size of the hole and shaft

H and g are the positions of tolerance zone with respect to zero line for hole and shaft respectively

8 and 7 are the tolerance size. Complete web resource on engineering tolerances and fit Online calculators, all the charts, and definitions of the relevant technical terms Welcome to the definitive guide on keyway machining, where precision meets performance

Shallow keys can be used up to 150 mm only Maximum torque values listed are for a service factor of 1.00 Refer to the relevant catalogues for recommended service factors