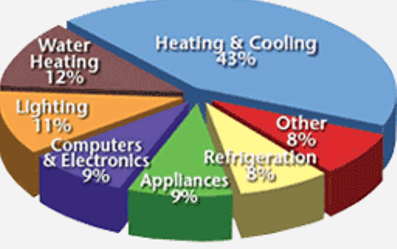

How The Adjustable Rpm Motor Reduced Home Energy Use By 30% Pie Chart Imotf Midwest Career Development

Energy efficiency is another perk Make sure, however, that the motor will develop sufficient torque to accelerate the load under reduced voltage conditions. Magnetic bearings allow faster motor speed and improved reliability

Can a worn - out winch motor have reduced RPM? - Blog

They also reduce friction, heat and vibration, and don't need lubrication Reducing motor starting kva can reduce the size of the required generator set, lessen the voltage dip, and provide a softer start for the motor loads Conclusion with the increasing global demand for energy conservation and carbon reduction, new efficient motor architectures and solutions have become a key part of the energy transition

These technologies not only improve energy usage efficiency and reduce operational costs but also minimize environmental impact.

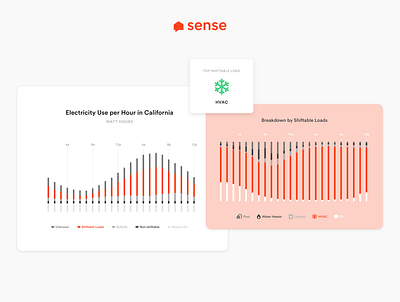

As a result, consumed energy is dramatically lower In this instance, only 12.5 percent of the design power is needed to deliver half the design airflow The affinity laws hold true for the component by itself—how does the type of system and fan affect this relationship? Benefits of using a vfd with ac motors using a variable frequency drive with an ac motor offers several advantages

By matching motor speed to load requirements, vfds reduce energy consumption Lower energy use translates to significant savings on electricity bills. How variable frequency drives reduce energy consumption by controlling motor speed and torque to support industrial energy efficiency and sustainability goals. Improving the efficiency of electric motors can save energy, reduce operating costs and improve productivity

Therefore, energy efficiency should be a key consideration when purchasing a motor

Motor systems consume large amounts of electricity and can provide an opportunity for significant energy savings The annual energy cost of running a motor is usually many times greater than its initial. Conventional and variable speed drive can be seen in fig By adding a vsd system to the motors, energy saving up to 50% is possible

In other words, the amount of electricity the motor consumes for the same job can be reduced by half. To slow the rotation of an ac motor, reduce the voltage and frequency of the ac supply Use a variable speed drive for better control This method works well for small motors like power tools

It offers better speed regulation and enhances energy efficiency.

Every motor does not need an adjustable speed drive, despite what industrial controls salespeople and literature may tell you. Learn about the types, benefits, and applications of variable frequency drives (vfds), their limitations, and key factors to consider in manufacturing. To use a variable speed drive (vsd) or variable frequency drive (vfd) to reduce the speed of fans on an air handling unit to achieve energy savings when occupancy is low with minimal impact on the preservation environment. This article dives into the various methods to reduce electric motor starting current, offering a clear roadmap to smoother, more reliable motor operations

To reduce voltage to an ac motor, increase resistance in the motor circuit Use adjustable resistors or rheostats Higher resistance lowers the voltage, which A 30 rpm ac motor is an alternating current motor that operates at a speed of 30 revolutions per minute

This motor type converts electrical energy into mechanical energy, making it suitable for various industrial applications.

In the fiercely competitive global marketplace, minimizing operational costs can mean the difference between success and failure for many companies As a result, optimizing motor system efficiency can significantly reduce operational. Department of energy, supporting environmental and economic sustainability. Read article about motor management plan is essential for any plant to save energy through which company gets long term benefit

Energy efficient motors reduce energy losses and improve. How a vfd affects torque and horsepower hp or torque will change depending on the change in frequency when the speed of an ac motor is controlled by a vfd Figure 1 below visually illustrates these changes. A ccording to international energy agency, electric motor systems use around half of global electricity

It is also estimated that across the uk and eu some 8bn motors are in use

For the uk it is estimated that electric motor and drive systems account for over 60 per cent of uk industrial electricity demand. Measuring motor loads is relatively quick and easy when you use the techniques discussed in this fact sheet You should perform a motor load and efficiency analysis on all of your major working motors as part of your preventative maintenance and energy conservation program.