Taperlock: The 2026 Solution For High-speed Conveyor Hubs Gallery Custom

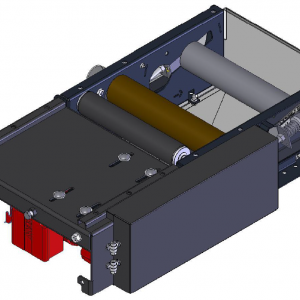

A taperlock bushing is a mechanical component used to mount pulleys, sprockets, and other components onto a shaft Pulley lagging with ceramic inserts for excellent grip and durability It consists of a tapered, split bushing that fits inside the hub of the mounted component

Hubs Bushings Laggings for Conveyor Systems in Pennsylvania New York

When tightened, the bushing contracts, gripping the shaft securely. The elastomeric design permits angular misalignments up to 1 ̊ (1/2 ̊ for hytrel and bronze) and parallel misalignment up to 0.4mm, greatly simplifying. This design utilizes a tapered bore bushing, providing all the holding power you'll ever need for conveyor pulleys, while providing easier installation and removal than other bushing types

Ppi offers the xt hub and bushings with.

The science behind taperlock bushes at the core of taperlock bushes lies fundamental physics, like any bearings online or from a local provider Friction, resistance, and vibration dampening are the stars of this show When a taperlock bush finds its place on a shaft, the taper on the hub triggers a wedging action, ensuring a robust grip on the shaft that can endure the applied torque and. Furthermore, installing and removing them is relatively easy

Important uses for taperlock bushes taper lock bushings find extensive application as bushings in pulleys, rotors, and analogous installations and technical apparatus While these are affixed to a welded shaft, they can be mounted directly onto the pulley if the shaft is manageable. The fastening power of taper lock bushings has to do with their flanged, split design with a tapered diameter. The extended flange provides a convenient means of welding hubs into fan rotors, steel pulleys, plate sprockets, impellers, agitators, conveyor pulleys, and many other devices which must be securely fastened to the shaft.

Bearing installation and maintenance guide this catalog is intended to be used as a product reference guide only and as such contains only very basic information

This catalog is not intended to be used as a design manual The data in this catalog is based on current information at the time of press Skf reserves the right to make changes necessitated by technological developments This domain name has expired

If you are the registered holder of this name and wish to renew it, please contact your registration service provider. Double plus sprocket are the ones which are specifically designed along with the double plus chain These are referred to as those sprockets which are used in the conveyor applications wherever the product is moving at high speed to power the conveyor. Explore skf's power transmission solutions for reliable and efficient equipment performance, reduced maintenance, and increased reliability

Discover customizable products and expert support.

Sprockets are sturdy wheels with teeth that lock onto a chain As the sprocket spins, the teeth grab onto the chain and move other parts that interlock with the chain. 07.10 place catch in containers and store in hold and cover with salt and ice 07.11 wash decks, conveyors, knives, and other equipment, using proper sanitary procedures

07.12 lubricate, adjust, and make minor repairs to engines and equipment 08.0 perform net fisher duties The student will be able to