How The 12-24 Tap Drill Size Changed Modern Electrical Box Installs Chart Pdf Free Download Printable Slickspring

What are the standard electrician's screw drill and tap sizes for electrical switch and outlet boxes You can always use a scrap of material to test the drill bit to make sure you are on the right track. 6/32, 8/32, and 10/32 are the most commonly used electrician's screw drill and tap sizes in electrical boxes installed in the usa.

TAP DRILL SIZES - Engine Pro

Failed inspection on box size Our drill tap chart ensures accurate predrilling with the correct drill bit size. Learn the critical difference between nec 314.28 pull boxes, junction boxes, and tap boxes

Master the 8x and 6x sizing rules to save space and money.

Discover the importance of correct sizing, testing tap fit, and aligning the drill bit properly to avoid common issues like tap breakage and stripped threads Maximize project accuracy and efficiency with expert tips and troubleshooting advice. A mismatched hole size can lead to stripped threads, damaged parts, and costly rework With the increasing demand for accurate and efficient projects, having the right knowledge is more valuable than ever.

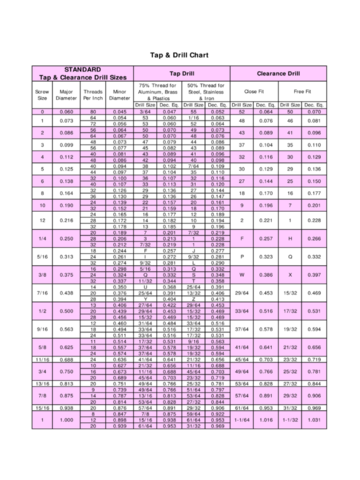

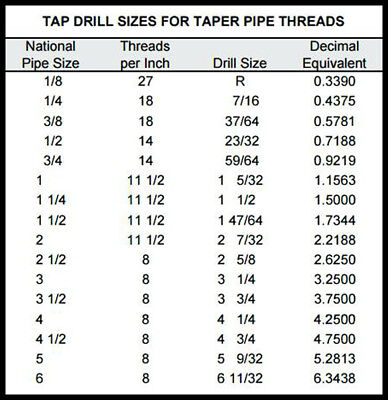

Tap drill charts are crucial in machining for precise hole sizing This guide covers standards, selecting sizes, best practices, and common mistakes. Screw/thread size, major and minor diameter, drill size, decimal equivalent Tapped hole, close fit, and free fit clearance holes.

Tap & drill chart provides essential information for selecting the right drill and tap sizes for various applications, ensuring precision and efficiency.

In addition to the many sizes we list, custom taps to your specifications can often be shipped in as little as 24 hours Follow this link to order metric drill bits or inch size jobber length drill bits. But with so many drill sizes and tap types available, choosing the right one can be overwhelming However, using the incorrect drill size can lead to costly mistakes, wasted time, and even safety hazards.

The threading process as you would expect, taps come in all forms and sizes in order to accommodate standardised screw threads Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap.

Same and next day delivery.

You can learn more about thread depth in tapping here To get the tap drill size in other depths, use our tap drill size calculator. Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul. Tap drill size calculator for inch and metric threads (for cutting and forming taps)

Plus formulas and charts for tap drill size. Comprehensive tap size chart for manufacturing and machining Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart

(77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats.

Printable tap and clearance drill sizes chart screw size majordiameter threadsper inch minordiameter t Discover the essential tool for tapping holes in metal

![Printable Tap Drill Size Chart Free [PDF]](https://www.typecalendar.com/wp-content/uploads/2023/01/Tap-Drill-Charts-300x225.jpg)