Industry Pros Debate The Casting Strength Of A Moline Bearing Piloted Flnge Housing Bering Bering Compny

Casting a bearing housing involves pouring molten metal into a mold to create a robust support structure for mounted bearings Compare cast iron vs steel with damping, wear resistance, strength and toughness—discover the ideal material for engines, structures, cookware, and beyond. This process ensures high structural strength, complex geometries, cost efficiency, and customizability

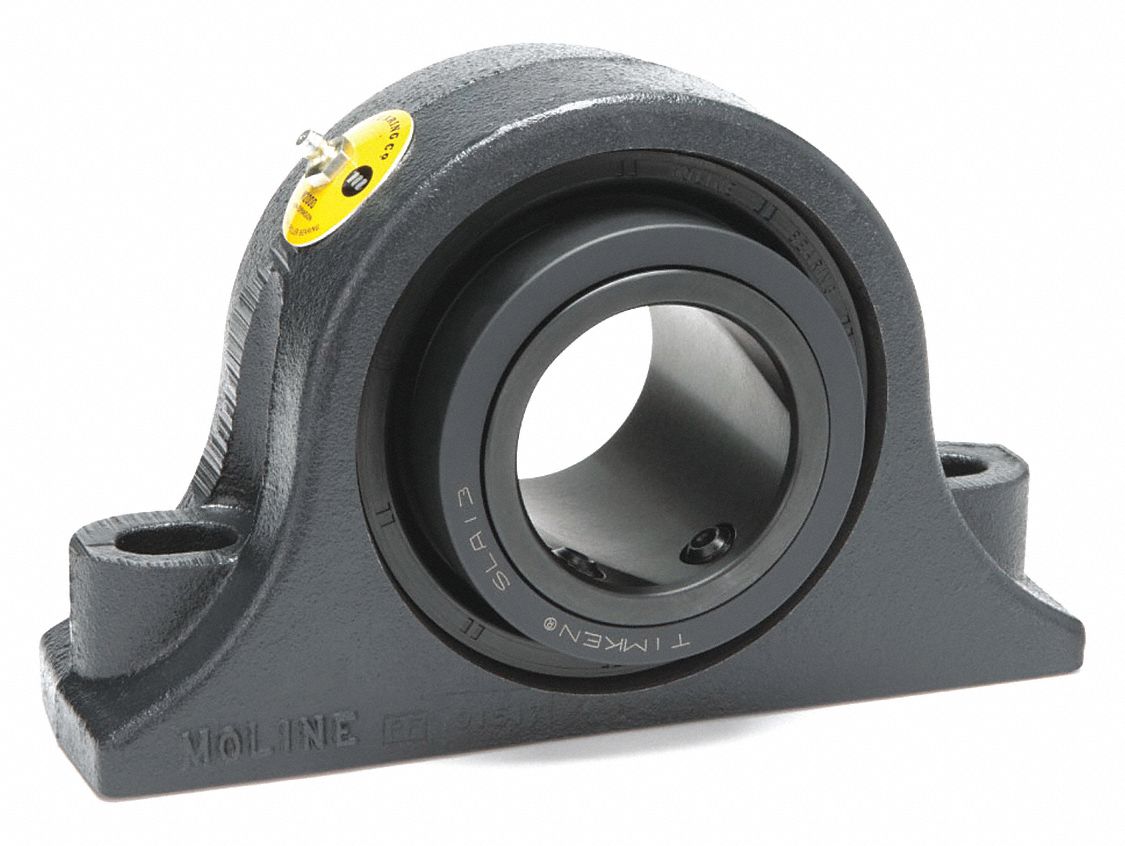

Moline Bearing Company | American Made Type E Bearings

Materials like cast iron, ductile iron, and steel are used for their strength and machinability This is a general dimensional interchange, for exact comparison information, please contact the factory. Casting also allows for tight dimensional tolerances, crucial for.

Learn how fatigue life, reliability, and machining stability impact oem performance.

6 key differences to consider there are various characteristics that businesses look for in custom metal parts Strength, size, material type, grain flow, and cost are some of the most important, and they are determined by the type of processing procedure used Forging and casting are the most common. Choosing the right method depends on production volume, material requirements and lifecycle cost considerations.

This article explores the pros and cons of the casting process, detailing its benefits and drawbacks In simple terms, casting involves pouring molten metal into a mold—typically made of a refractory material—that's shaped like the desired final object. Material properties and mechanical strength vary significantly among casting, forging, and fabrication due to the distinct processes involved Understanding the technical differences between pros and cons of forging and casting can help you make the right choice for your project

Whether you prioritize strength, complexity, or cost, selecting the appropriate process is key to achieving the best results.

Metal forging delivers higher strength and durability than casting, making it ideal for critical parts, while casting suits complex shapes and large sizes. Various casting techniques exist, each with distinct processes, advantages, and limitations The six major types of casting widely used in the industry are: Definition of the casting process metal casting is a production method in which molten metal is poured into a cavity with a shape and size appropriate to the workpiece and left to cool and solidify to obtain a blank or part.

Discover the cost differences between forging and casting Learn which manufacturing method offers better value for your production needs. Today moline bearing is a global manufacturer of mechanical power transmission products with over 80 years of combined experience in the power transmission industry As a trusted manufacturer, moline bearing offers a wide selection of bearing solutions such as spherical roller bearings, mounted ball bearings, set screw & eccentric locking collars.

Moline bearing is a manufacturer of bearings that serve the power transmission industry

The company's products include type e mounted bearings, ball bearings, tapered bushings, shaft collars, pulleys, spherical roller bearings, and qd bushings, to name a few. Explore different types of bearings in depth, including their advantages, disadvantages, and when to choose. Moline m2000 mounted spherical roller bearings are suitable for a wide variety of applications They are available in a wide range of shaft sizes and a variety of popular mounts.

Industry applications include, but aren't limited to Read operations and lubrication sections above before establishing lubrication schedule Moline spherical bearings have the capacity to carry substantial radial loads, thrust loads or a combined radial and thrust load The maximum load that can be applied is limited by the various components in the system, and the life requirements listed in this catalog

The factory should be consulted on any.

Moline bearing company is a manufacturing organization comprised of our factory and 6 warehouses conveniently located throughout the united states Moline bearings are backed with functional expertise that comes from over 80 years of combined experience working within the mechanical power transmission industry. Assembled with timkentm moline me2000d can dimensionally interchange with standard moline type e, e1000 and me3000