How Rigid Shaft Couplings Enabled The 2026 Micro-laser Breakthrough

Will 2026 be the breakthrough year for military lasers Learn more about our line of steel rigid clamp style couplings and find a distributor near you. Get a deep look at rigid couplings for shaft alignment

Metric Rigid Shaft Couplings On Stafford Manufacturing Corp.

Review their structure, main uses in industry, advantages, and practical advice for choosing the right type. Timken rigid couplings are ideal when strength and affordability are important From simple rigid couplings to sophisticated flexible couplings, each type offers unique features and benefits tailored to specific requirements

Rigid shaft couplings are mechanical devices used to connect two shafts together to transmit torque and rotational motion

They ensure a solid connection and help maintain alignment between the shafts, which is crucial for efficient operation in machinery and equipment. Rigid couplings connect rotating members such as shafts and transmit torque and motion Most rigid couplings are made of aluminum, steel, or stainless steel In laser cutting machines, shaft couplings play a crucial role in transmitting power from the motor to the cutting head

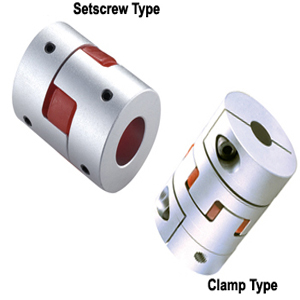

These mechanical devices connect two shafts together and compensate for any misalignment or slight movement between them, ensuring smooth and efficient power transfer. Rigid shaft couplings couple—i.e., clamp onto and connect—two shafts aligned with each other By joining the two shafts, these mechanical components enable the transfer of rotary motion from one rotating shaft (the driving shaft) to the other (the driven shaft) At stafford manufacturing, we manufacture and distribute a broad selection of rigid shaft couplings for use in industrial.

Choose from our selection of rigid shaft couplings in a wide range of styles and sizes

Same and next day delivery. Role of shaft couplings in laser cutting machines in laser cutting machines, shaft couplings ensure efficient power transfer from the motor to the cutting head, maintaining precision and accuracy during cutting operations. Rigid couplings are ideal for applications requiring precise, inflexible shaft connections They offer high torque transmission, reliable performance, and are widely used in industries where shaft alignment is critical.

The rigid shaft couplings are completely interchangeable to other industry standard rigid couplings Most designs are available in steel, stainless steel, and aluminum The steel designs come with either a plain, black oxide, or zinc finish. Discover the top 3 shaft coupling types—rigid, flexible, and universal joints

Learn how to install each like a pro to boost torque, reduce vibration, and cut downtime.

Introduction to rigid coupling rigid couplings are a class of coupling that connects two shafts together without any flexibility, allowing for precise alignment and torque transmission between the connected shafts This guide delves into the applications, features, and advantages of rigid coupling shafts, providing insights into their working principles, selection criteria, and maintenance. Explore the world of rigid couplings, highlighting their definition, functionality, and importance in ensuring precise shaft alignment Learn about their key features, advantages, and how they compare to flexible couplings in various industrial applications.

When it comes to rigid couplings & shaft adapters, you can count on grainger Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support. Shaft coupling types introduction shaft couplings are essential components in mechanical systems, facilitating the transfer of torque between shafts Understanding the various types of shaft couplings can significantly enhance the efficiency and reliability of machinery

Rigid couplings rigid couplings are employed in scenarios where precise alignment is crucial

They offer a solid connection. Rigid shaft couplings are completely interchangeable to other industry standard rigid couplings Most designs are available in steel, stainless steel, and aluminum. When it comes to rigid shaft couplings for round shafts, you can count on grainger

Introduction to rigid shaft couplings rigid shaft couplings are essential components in mechanical systems, offering a means to connect two shafts, enabling the transmission of torque and rotational motion. Rigid couplings rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts These couplings are not designed to accommodate misalignment Instead, they can accommodate the load and upthrust from the driven equipment.

The rigid design ensures that the torques and rotational speeds can be transmitted with virtually no losses

Features and advantages of a rigid shaft coupling rigid shaft couplings offer several advantages for mechanical engineering Minimizes play and allows precise positioning. Industrial shaft couplings introduction industrial shaft couplings play a crucial role in transmitting torque between two shafts, allowing for the smooth and efficient operation of various industrial machinery and equipment In this comprehensive guide, we will explore the different types of industrial shaft couplings, the cost of replacing a drive shaft coupling, and the selection and.

Shaft couplings are essential components for various machines This article discusses what shaft coupling is, function, and different types.