How The 1750/20 Specification Is Changing Industrial Pump Flow By Jernstberger Simscale

The amt cast iron 1750 rpm solids handling end suction centrifugal pump delivers performance that minimizes operation and energy costs Vertiflo pump company has a great selection of industrial pumps to fit your requirements for industrial, commercial, agricultural, or municipal process Built to last, each pump features a precision cast bronze impeller that is dynamically balanced to minimize vibration and maximize motor bearing life.

Industrial Pump Repair Fort Wayne - Horner Industrial

This manual covers the installation, operation and maintenance of amt 1750 rpm centrifugal pumps For a new pump, our calculations of total head for a given flow rate will have determined the impeller diameter to select according to the performance curve These pumps are a centrifugal, single stage

Single suction type furnished with mechanical seals

When properly installed and when given reasonable care and maintenance, centrifugal pumps should operate satisfactorily for a long period of time Centrifugal pumps use the centrifugal force principal. Find the head under these conditions Pump is drawing from an open tank to discharge through a heat exchanger into an open tank that is 20 ft

The supply is 8 ft 50 gpm flow is required. The close clearances combined with the rotor geometry, which gives a long sealing path between the pump inlet and outlet, means low slip operation As a result, you achieve

High volumetric efficiency and good flow control.

Built to last, each pump features a precision cast bronze impeller that is dynamically balanced to minimize vibration and maximize motor bearing life Gauge taps at the suction. When properly installed and when given reasonable care and maintenance, centrifugal pumps should operate satisfactorily for a long period of time. While small pumps in parallel will often provide a solution, it is decided to apply speed reduction to 150 rpm.

Pump flow for 1750 rpm pumps Hp gpm at 60 hf (25 psi) gpm at 80 hf (34 psi) gpm at 100 hf (40 psi) gpm at 120 hf (50 psi) 2 80 gpm 3 100 gpm Centrifugal 1750 rpm pumps, cast iron w/ bronze impeller construction with flanged ports Cast iron 1750 rpm solidshandling end suction centrifugal pumpdelivers high efficiency performance thatminimizes operation and energy costs.

The formula incorporates the pump's mechanical characteristics to provide a direct measurement of flow rate in gallons per minute (gpm), a common unit in hydraulic systems.

M03 series maximum flow rate 3.1 gpm (11.7 l/min) maximum pressure 2.4.6.4 for centrifugal pumps, use a maximum of 140% of the pump rated flow capacity to meet the combined system demand and hose streams (if also supplied by the fire pump), if one 100% qmax pump is used. To increase the flow rate, you could also put in a bigger pump, often it is easier to change the pipe or tube than to change the pump

In practice, to get the optimal system you have to select the pump capacity (i.e Flow rate) and head in conjunction with the right pipe or tube size to get the flow rate you intend at the destination. Fire pump quick start guide are you a member of an apparatus committee that is working to create a spec for your new apparatus Lists specific details and technical specifications of various pumps including hydraulic oil transfer and transfer pumps

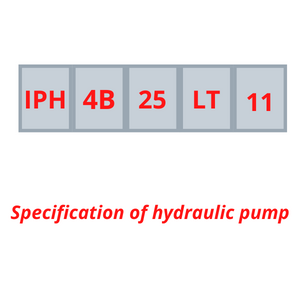

Presents technical drawings and specifications for centrifugal pumps with counter flanges and associated components.

Peerless pump manufactures vertical turbine pumps, hydrofoil pumps, axial and mixed flow, in a variety of configurations and materials Ask about the variety of drives available to deliver solutions for all applications and markets. W+ centrifugal pumps are designed to achieve lifetime cost savings and lower energy consumption. John deere 1750 tractor technical data

At some point in the pump selection process, the impeller diameter is selected For an existing pump, the diameter of the impeller is known