The Viral Design Dispute: When To Use Flexible Coupling Versus Rigid Sleeves

Flexible couplings and rigid couplings each have their distinct advantages and applications in power transmission systems Couples two machines while absorbing the (parallel an d angular ) misalignment s of the shafts to transmit rotational angle and torque. By understanding the differences between these two options and carefully assessing your specific requirements and operating conditions, you can make an informed decision to choose the right coupling for your application.

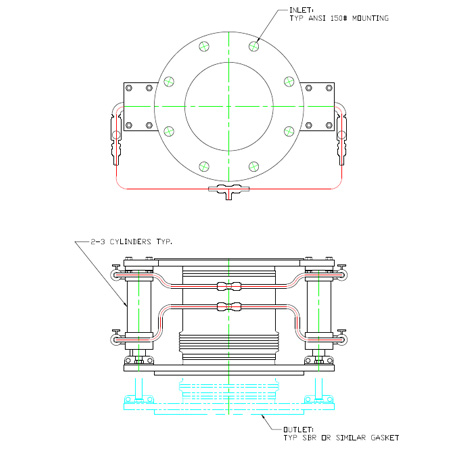

FLEXIBLE AND RIGID SLEEVES - Romag

When to use rigid vs Flexible couplings often use elastomeric inserts, of spring steel plates or rubber, to absorb axial misalignment (eccentricity) or angular misalignment (declination) Flexible couplings choosing between these two coupling types depends on how your system operates

In contrast, you should use flexible couplings for systems where there is misalignment, vibrations, and in systems where a protective function is needed to protect more expensive components of the drive train.

Rigid and flexible couplings transfer torque Learn their differences, misalignment tolerances, and ideal use cases. When engineers consider connecting and transmitting power in mechanical systems, couplings are often the key components that they prioritize With a wide variety of coupling options available, this article will compare two of the most common types

Rigid couplings and flexible couplings, across three key aspects Comparison of performance and function rigid couplings Explore the pros and cons of flexible vs rigid couplings in machinery Learn which coupling type suits your application for optimal performance.

Couplings are critical components in mechanical systems, serving to connect two shafts together for the purpose of transmitting power

The selection of the appropriate coupling type is essential. Understand the difference between rigid and flexible sleeve couplings Learn how to choose the right one for efficient and reliable power transmission systems. Discover the differences between flexible and rigid couplings, including their applications, torque transmission capabilities, and maintenance requirements, to select the optimal solution for industrial machinery.

In essence, rigid couplings are the ideal choice for absolute precision and power transmission without any margin for flexibility Flexible couplings, on the other hand, are specially designed to compensate for some degree of misalignment between connected shafts. Types of shaft coupling, its uses, drawings, and applications, and more also download the pdf file of this article. The first grooved mechanical pipe coupling invented was a flexible pipe coupling

Learn how they are different from rigid pipe couplings.

When two shafts are properly connected by a rigid coupling, they operate as a single shaft Rigid coupling does not permit relative motion between the shafts of the driver and driven machines A rigid coupling is primarily used for vertical applications, e.g., vertical pumps Flexible coupling is used to connect two axially oriented shafts.

A gib head sunk keys hold the two shafts and sleeves together The structure, design & working principle of sleeve coupling so far, we are somewhat familiar with jaw couplings and know what they are basically used for Let's take a closer look at how jaw couplings work. Learn what are the advantages and disadvantages of rigid and flexible couplings and how to select the best one for your machine design.

Flexible couplings transmit torque between shafts while compensating for misalignment

However, due to their design, there might be some loss of torque transmission compared to rigid couplings Rigid couplings provide efficient torque transmission between shafts as they have no flexibility. This adaptability is the key factor that distinguishes flexible couplings from rigid ones, allowing them to perform effectively in scenarios where shaft misalignment and dynamic forces are present Therefore, in comparing rigid couplings and flexible couplings, we can identify the following 3 key aspects to illustrate their differences

Depending on the design, alignment, and load conditions of the shafts, you may need to choose between rigid and flexible couplings In this article, you will learn what are the advantages and disadvantages of each type of coupling and how to select the best one for your machine design. Solid rigid shaft to shaft couplings design equations and calculator The a shaft to shaft solid coupling does not allow for misalignment, except axial, but enables the extension from one piece of equipment to another.

When connecting pipes in industrial applications, it is crucial to understand the difference between rigid and flexible couplings

This study focuses on exploring the features, benefits, and uses of rigid and flexible couplings to guide you in making an informed choice for your piping needs. Choosing the right coupling makes all the difference From flexible to rigid couplings, each type serves a unique purpose depending on torque, load, and shaft size. Flexible couplings unlike rigid couplings, flexible couplings can accommodate some movement e.g

Vibrations and thermal expansion without damage This makes them ideal for applications where there is a degree of unavoidable misalignment between the drive and pump shafts.