Deep Dive Into The Strategic Grip Logic Of The Newest Vee Belt And Pulley Sets Sheaves A B C Types Whats De Difference? Cr4

What are vee belt pulleys All i find are about cogged belt timing pulleys or measuring groove wear with a gauge This design ensures a secure grip.

Philips VS Samsung deep dive into strategic leadership and

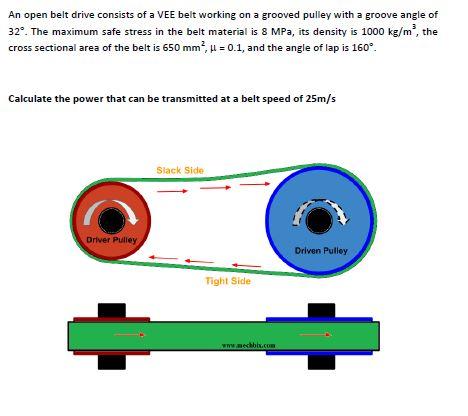

The shape of the belt creates a wedging action, increasing friction and reducing the chance of slippage, even under high torque or heavy load conditions I can not remember how to read the numbers on a vee belt pulley This means that vee belts can handle the rigorous demands of.

A friction drive connects two shafts by a belt that is drawn taut enough to grip each shaft and turn them

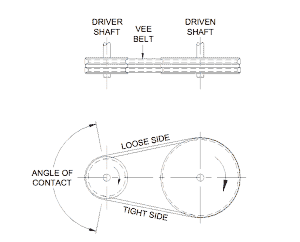

Each shaft has a pulley attached to it The belt is pulled tight to create friction with the pulleys As the drive pulley turns, the belt moves the connected driven pulley Figure 1 show elevation and plan views of a twin belt drive.

Invented by john gates in 1917, their easier tracking on pulleys and higher friction (which we'll explain more on a moment) also allow high force transmission even at relatively low tension values The power transmission rating of a vee belt drive is based on the belts used, the number of belts, the angle of wrap of the belt on the smallest pulley,and the rotational speed of the pulleys. Several factors influence the friction, including belt tension, pulley material and size, and the angle of the vee grooves Aluminium vee belt pulleys find their place in numerous applications across different sectors

Let's explore some of the key areas where these components make a significant impact

Belt pulleys are fundamental components in various types of equipment, ensuring smooth and efficient operation For those involved in industries like manufacturing, agriculture, or automotive, understanding what vee belt pulleys are and why they matter is essential This blog will get into the details, explaining their function, types, and significance For power transmission to your buzzsaw how about a jack shaft mounted on pillow blocks with a v belt pulley on one side and a flat belt pulley on the other

Different size pulleys will create your Gear ratio that you need. Compared to other pulley types, poly vee pulleys offer superior performance in terms of efficiency, compactness, and power transmission However, selecting the right pulley type depends on specific application requirements.

Was your belt sitting at the top, maybe with the belt hanging slightly over the flanges of the pulley

If so, take a look at the belts that fit information on your pulley's page. A v belt pulley is suitable for use in pulley systems that feature a v belt The pulley provides a mechanism that is easy to install and replace if necessary These v belt pulleys are typically used in the industrial and automotive sectors, as they offer advantages when compared to other methods of transmission.

Power and precision the dual pulley lat pulldown is a more advanced machine that offers a unique set of benefits Advantages of the dual pulley The dual pulley system allows you to lift heavier weights, leading to greater muscle growth and strength gains. Durable, efficient power transmission solutions for industrial, automotive, and machinery use.

I troubleshoot power steering pump drives just about every day.

This is part 1 of 2 part 2 shows boring to size, broaching the keyway and shrinking to the. The functionality of pulleys pulleys are mechanisms […] How it works, its components, design, advantages, disadvantages and applications. Discover the key components and operational dynamics of belt conveyors used in material handling systems

Explore their design, function, and crucial roles in transporting cargo efficiently across various industries.