Shaft Seals: New 2026 Zero-leak Standards For High-pressure Chemical Labs China Customized Process Pump Manufacturers Suppliers Factory

Why rotary shaft seal trends in 2026 matter to oems and suppliers context for oems and buyers the rotary shaft seal remains a small component with outsized impact on equipment life, energy efficiency, and environmental compliance Pump bottom leak fix how to fix leaking pool pump | pentair challenger motor shaft seal replacement & housing gasket leak The choice of polymer directly dictates its resilience against chemical degradation, temperature extremes, and physical wear

China High pressure chemical pump Suppliers, Manufacturers - Factory

Using substandard materials is a primary cause of premature seal failure, leading to costly downtime and environmental contamination. Hayward super pump shaft seal replacement Modern industrial applications present formidable challenges for rotary shaft seals

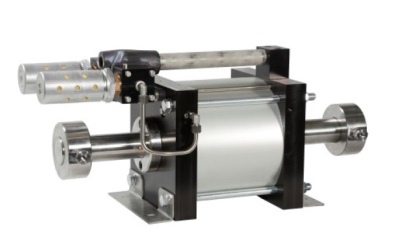

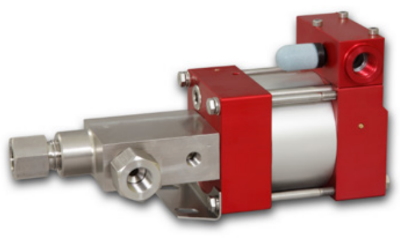

Engineered for reliability and longevity.

Rotary shaft seals, lip seals and fluid seals that minimize friction and extend service life in high and low speed operation. Machines require rotating shaft seals to retain lubricants and prevent foreign particles from entering sealed cavities, which damage machinery and lead to premature failure Application conditions can vary considerably, and many seal designs have evolved to satisfy these conditions Some applications tolerate a small amount of leakage, while others cannot allow any leakage

Shaft seals fail due to misalignment, dry runs, improper installation, chemical degradation, and excessive pressure or temperature Leaks, shaft wear, and system vibration are common symptoms. Pool pumps are essential for keeping your pool clean and clear, but when they go bad, it can be a real mystery One of the most common problems pool owners

In a single type mechanical sea pump, the liquid is normally the fluid already bein h

A seal can be exposed to a wide variety of operating conditions—sometimes very different from conditions the seal was intended for—which can cause issues down the line However, even if your seal is the right one for the job, there can be times when it fails faster than anticipated. Radial shaft seals are vital to the performance and longevity of rotating machinery, ensuring effective sealing between moving components This comprehensive guide explores the key design principles—tolerances, surface finishes, fits, and standards—that govern successful seal performance.

How do you calculate the leakage rate of a mechanical seal Mechanical seals are precision devices that are designed to seal a rotating shaft However, they do rely on a small amount of leakage to lubricate and cool the seal faces. The dimensions on the replacement seals were ok and the seals were pressure rated at 6 bar

Installed a spacer ring to move the lip contact to the shaft to a healthy surface, packed it up and put it to the test bench.

Polyurethane is often used in the production of lip seals due to its excellent wear resistance and flexibility Shaft seals excel in hydraulic and pneumatic systems due to their wear resistance and ability to withstand high pressures. Hayward pool pump seal replacement