Data Insights: Why Modern Gear Reducer Designs Are Achieving 99% Transmission Principle Of A Acg And B Rv

Index terms—optimization design, gear reducer, adaptive boundary constraints, performance parameters i Fatigue analysis of reducer transmission parts liang wang, yan shi school of mechanical engineering, sichuan university of science & engineering, yibin, sichuan 644000, china Introduction with the advantages of large transmission power and high efficiency, gear drives are widely applied in the fields of construction machinery, auto industry, etc., and play an important part in the modern industries.

Hot Rolling Mill Reducer Zd Series Reducer Single-Stage Gear Reducer

In most industrial robots, two relatively unconventional transmission technologies—harmonic drives© and cycloid drives—are usually found, which are not so broadly used in other industries The fatigue analysis is mostly used in the calculation process. Understanding the origin of this singularity provides valuable insights in the search for suitable, future robotic transmission technologies.

Key gear types and functions cylindrical gears

Spur and helical spur gears are the old reliable for parallel shafts Helical gears cost more but run quieter and carry heavier loads in the same space Almost every electric car gearbox and robot joint uses helical gears somewhere in the train. The purpose of the study is research different types of gear and ways using them

After that, applying results from the researching knowledge to design a stable and efficiency gear box used in belt conveyor system Learn machine component design fundamentals with this textbook Covers mechanics, materials, fatigue, and applications for engineering students. Modern domesticated soybean has a significantly higher oil content than its wild counterpart so oil content is potentially a source of new insight into soybean domestication

Shutterstockコレクションで「Humanoid robots」のHD動画素材やその他の数多くのエディトリアル動画を見つけてください。数千点の新しい高品質動画が毎週追加されます。

This document provides an overview of the design of industrial gear boxes The document contains examples and calculations to illustrate different aspects of. Video answers for all textbook questions of chapter 12, shaft design, machine elements in mechanical design by numerade Harmonic reducer is a critical and vulnerable component of industrial robots

Its dynamic rules are difficult to express because harmonic reducers always operate under continuously varying operating conditions in practical application scenarios How to achieve fault diagnosis under dynamic operating parameters is a challenge This paper proposes a fault diagnosis scheme for harmonic reducer. In 2011, the american society of civil engineers (asce) estimated an average expenditure of $27.5 billion annually for electric transmission and distribution investments in the united states, and they predict a cumulative investment shortfall of $331 billion by 2040.8 the average annual expenditures estimated by asce are consistent with data.

Specifications ensure gears and bearings satisfy customer requirements for power and torque

Safety factors for wear and bending are considered with reliability set at 99% Load ratings for bearings are crucial, with a design life of 12,000 hours specified. Home goods, electronics, & beauty p by garnet gazelle Auction will be held on thu jan 08 @ time tba at 1321 upland dr pmb 16334 in houston, tx 77043

See photos and more auction details on auctionzip.com now. Identical pairs of gears are used (this enables input shaft a and output shaft c to be colinear, which facilitates machining of the gear box housing) Shaft b, also called the countershaft, turns freely in bearings a and b

Suppose the system is to run 8 hours per day, 5 days a week, and last for 10 years.

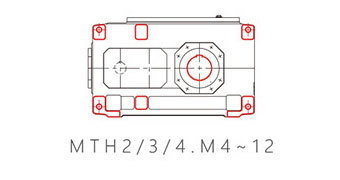

Minimum design life for bearings is 5 years Use 108 cycle 99% reliability data at full load conditions above Use infinite life for the full load output case, because of the high number of load cycles. Summary the rv reducer is one type of two stage cycloid reducers which are widely used in many fields of engineering

This project has designed the first stage of the rv reducer, as well as the related components The details contain design of input shaft, planetary gears, output shaft, common bearings and eccentric bearings

.jpg?itok=-ChcGnLr)