Precision Stats: How Flexible Coupling Technology Reduces Harmonic Vibration Industrial Hardware 40631 High Misalignment Shaft

Compliant joints are widely used in precision positioning stages due to their nearly zero friction For example, in the field of industrial robotics, harmonic drives can provide high precision and high load transmission, making the movements of robots smoother and more accurate. The kinetic and strain energies of the moving stages in.

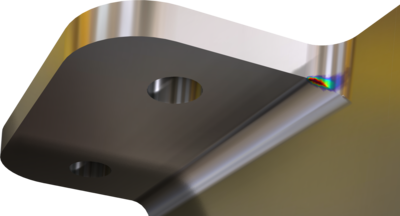

High Precision Double Diaphragm Coupling Flexible Disc Coupling High

An effective vibration control approach to minimise these effects is yet to be thoroughly investigated The working principle of harmonic reducers makes them widely applicable in many fields The vibration attenuation provided by three (3) victaulic flexible couplings installed in close proximity to the source vibration is superior when compared to double sphere rubber connectors and stainless steel braided pump connectors.

Vibration suppression in flexible mechanical systems (fmss) significantly enhances the precision and stability of equipment, extending its operational life

This technology is extensively applied across various sectors, including aerospace, robotics, and precision manufacturing This paper introduces a robust control scheme leveraging a partial differential equations (pdes) model and barrier. To study the contact mechanical characteristics of flexible components such as flexible bearing and flexspline in harmonic gear reducer, the contact mechanical model of flexible bearing, vibration differential equation of flexspline, and finite element model of each component in harmonic gear reducer were established. Then, the influence of boundary conditions, connection conditions and excitation on the vibration responses are investigated by different case studies.

Faulty machinery significantly increases vibration, particularly in the coupling, which leads to catastrophic failure of essential machinery components and, in some cases, worker life. Flexible and vibration dampening gear couplings Precision and no lubrication required grid couplings Vibration dampening with high torque capabilities fluid couplings

Ideal for soft starts and load protection choosing the right coupling

Couplings to the rescue drive shaft couplings with flexible elastomer components are commonly used to reduce the transmission of noise and vibration as well accommodate shaft misalignments. Magnetic couplings are flexible couplings which connect systems without direct mechanical contact by using magnetic field to transmit torque Due to this lack of contact, this type of coupling has application in precision conscious systems such as pumps, mixers, and sealed systems. Dpi was the first company in japan to introduce the metal plate spring (flexible disc) type coupling technology, which was brought to the united states from england, and has provided the technology to all industries to this day

Our disc type couplings are characterized by long lifespan and easy maintenance. We're on a journey to advance and democratize artificial intelligence through open source and open science. Design dampens torsional vibration and shock to help extend life of the coupling and surrounding components Quick flex inserts help reduce downtime and replacement costs because inserts can be replaced without moving or disassembling the driving or driven equipment.

Advancements in servomotor coupling technology flexible couplings are machine elements that fasten drive shafts and transmit torque while allowing for multiple forms of misalignment such as lateral, angular, and axial

Various flexible coupling types have been developed based on application demands. This method lays a foundation for fault diagnosis of small size precision structures, and may be applied to harmonic reducer precision components [10] analyzed the influence of harmonic reducer stiffness on vibration Coupling corporation's flexible couplings and anderson clamp hubs meet the nuclear power industry's need for reliability, dependability and maintenance free performance.

3, inf is proposed to address the resonance phenomenon. Flexible shaft couplings provide torque transmission while helping to improve machine performance and life, but using a low performance coupling or the wrong type of coupling can impede mechanical performance, reduce throughput, and even cause downtime.