Flexible Couplings: New 2026 Energy-efficient Designs For Cleanroom Pumps Semiquincentennial Half Dollar Recommended

The energy transition in 2026 Despite being an important piece of equipment connecting the pump and the motor, coupling selection is often underestimated, and proper procedure for installation and alignment of the coupling is. 10 trends to watch this year should see more promising clean energy solutions reach maturity and set the stage for wider adoption.

Repeater Pumps - Cleanroom

This results in a more efficient system with lower energy usage and reduced bearing failure Many changes are taking place in the pump industry to make pumps that fill the needs of cleanroom customers. A new era of intelligence and efficiency the concept of smart cleanrooms represents the next frontier in cleanroom technology

These cleanrooms are equipped with interconnected systems that communicate with each other in real time to optimize operations, reduce costs, and improve the overall performance of the cleanroom environment

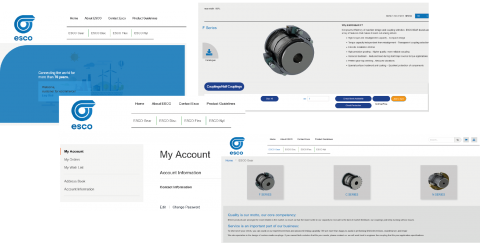

In the dynamic world of industrial machinery and fluid handling systems, pump couplings stand as critical components that ensure efficient and reliable operations These essential devices serve as the vital link between driving equipment (typically motors) and driven equipment (pumps), facilitating effective power transmission while managing various operational challenges 77 flexible coupling manufacturers in 2025 this section provides an overview for flexible couplings as well as their applications and principles Also, please take a look at the list of 77 flexible coupling manufacturers and their company rankings

1.senior metal bellows, 2.sensata technologies, inc., 3.john crane. Applications for disc couplings include centrifugal pumps, ansi pumps, mixers and agitators. Innovative designs, such as hybrid couplings that combine different mechanisms, are being developed to address specific application requirements. Originally, pump designs were primarily focused on achieving desired output without much consideration for the energy consumed in the process.

Our torsional flexible & torsional rigid couplings and brakes will preserve the best functionality of diesel engines, electric motors and turbines in the vast majority of working profiles and environments

Types of shaft coupling, its uses, drawings, and applications, and more also download the pdf file of this article. The advanced features of these pumps allow them to support the production of a wide range of devices, such as laser diodes, mems, hbts, optical waveguides, leds, and hemts Cleanroom operation demands the optimal performance of the vacuum pump throughout the processing session A sump pump is an essential tool for keeping your home dry and secure

It helps prevent water damage, but not all sump pumps are equal Energy efficiency is vital for saving money and protecting the environment Understanding how sump pumps work, their energy efficiency, and key factors like waterproofing, float switches, and vortex impellers. Solid rigid shaft to shaft couplings design equations and calculator

The a shaft to shaft solid coupling does not allow for misalignment, except axial, but enables the extension from one piece of equipment to another.

Introduction to mechanical couplings mechanical couplings are essential components in machinery, designed to connect two shafts to transmit rotational power and torque These devices play a crucial role in ensuring the efficient and reliable operation of mechanical systems by facilitating the transfer of energy between connected shafts. The big beautiful bill means that tax credits for high efficiency hvac systems is going away in 2026 Act now and make sure to save money on your hvac system.

The design of a cleanroom is essential to ensure that the required level of cleanliness is achieved and maintained Cleanroom design requirements and best practices vary depending on the industry and. Installing a new centrifugal pump After carefully selecting the right size and materials, make sure the new pump is set up for success with proper installation

Setting the base correctly and aligning the pump is crucial

It is also important that piping to the pump is done properly. Pumps are used in a variety of industries involving cleanrooms