Improving Legacy Machinery Performance By Standardizing 15/16 To Mm Components Cusm Materials Project Profile

Machine retrofitting offers a practical solution by upgrading existing machinery with modern technology to enhance efficiency, safety, and productivity An o ring size chart provides standardized reference data that allows engineers, technicians, and maintenance teams This article reviews machine retrofitting, its benefits, common retrofit types, and why working with.

Machinery performance analyst | PDF

Many existing retrofitting approaches focus on isolated technical solutions without providing a structured and transferable methodology applicable to various industrial environments. Online weight measurement and correction, ensuring consistent weight during high speed productions. Faq what are legacy machine retrofits

Legacy machine retrofits involve upgrading older industrial systems with new control components without replacing the entire equipment, helping improve compatibility and efficiency

Why are retrofits important for legacy control systems? Why reverse engineering is essential for legacy components many industries still rely on legacy machinery and components that lack modern digital documentation When these parts wear out or break, businesses are often left with costly downtime or expensive redesigns 3d laser scanning and reverse engineering offer a solution by:

Upgrading controls and automation can extend the lifespan of legacy equipment This is particularly important for companies that have made substantial investments in machinery and want to maximize their return on investment Modern controls and automation systems can significantly improve the efficiency of industrial processes. When incorporating legacy parts into a new design, it is essential to ensure compatibility with existing manufacturing equipment and processes

This may involve designing components with the same dimensions or interfaces to fit seamlessly with older machinery

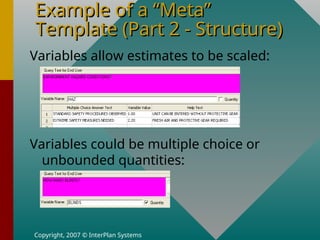

By making all parts available at all points of use, standardization improves flexibility and reduces costs for manufacturers Manufacturing standardization is the process of developing and implementing. Retrofitting in the industrial context refers to the modification and upgrading of existing machinery, thereby enhancing its performance and efficiency This process involves the integration of advanced technologies into older equipment, extending its service life and enabling it to function at a level that keeps pace with modern demands.

Research legacy systems & digital transformation a guide for faster evolution the equipment cost itself is sometimes not that significant, but the integration and support required for hundred of pieces of machinery significantly impact operating costs and complexity. — greg geihsler , technical director, proctor & gamble Explore practical strategies in application engineering aimed at improving mechanical design processes and boosting system reliability for industrial use. Same and next day delivery. Answer to q1xyz manufacturing recently implemented a softwarequestion

Q1xyz manufacturing recently implemented a software update aimed atimproving the consistency of its machinery for producing metalcomponents

Prior to the update, the process produced componentswith an average diameter of 108 mm , which is slightly below thespecification limits of 100 mm (lower) and 120 mm. This blog post explores the essential role of standardization in industrial engineering, detailing its history, benefits, and challenges It highlights how uniform guidelines enhance operational efficiency, improve quality assurance, and promote safety in production processes. By combining the results of performance (speed), quality (total good parts), and time (standard vs

Study with quizlet and memorize flashcards containing terms like from your reading of the chapter's opening case, which of the answers below is not a reason why lenzing chose jda's sales & operations planning software Minimize the environmental impact of its products b Improve sales forecast accuracy c Develop a new business model d

We meet our customers' expectations

Tires built on our machinery meet leading car manufacturers' requirements, especially with respect to uniformity. Significant improvement in load capacity, wear resistance, friction coefficient etc Hub bearing generation i refers to the first generation of hub bearings designed for automotive applications These bearings are crucial components that support the wheel assembly, allowing for smooth rotation and stability in vehicles

They typically consist of a combination of ball bearings or roller bearings housed within a durable casing. Prevent breakdowns, optimize performance, and follow best practices for lasting efficiency! Legacy 6100 tablet press main features of legacy 6100 Improved yield with control on dusting, content uniformity and contamination

Online sorting of out of specification tablets at high speeds ensuring good product quality