Understanding The Predictive Maintenance Strategy Built Into Every Skf Bearing Unveils Solid Oil Technology

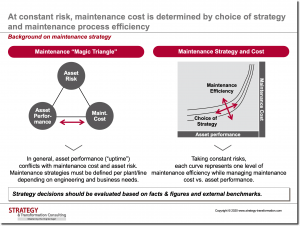

Working closely with the mill personnel, skf consultants selected the skf streamlined reliability centred maintenance process as the best methodology for the project According to deloitte, it's estimated that poor maintenance strategies can reduce a plant's overall production capacity from between five to 20 per cent. The maintenance strategy review covered the rotating, electrical and instrumentation components for the mills blank ring press machine, multi mandrel ring rolling machine and axial closed die rolling machine.

SKF Unveils Solid Oil Bearing Technology

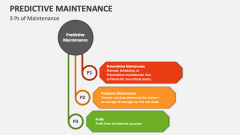

This blog explores how skf bearing solutions are transforming industrial processes through predictive maintenance and operational excellence, positioning the company at the forefront of industry 4.0. Here, chris johnson, managing director at specialist bearings supplier, smb bearings, explains the crucial role smart bearings play in predictive maintenance Establish a predictive system the first step is to design a predictive maintenance (pdm) system specifically for your plant, based on information provided via an skf assessment which enables us to understand the parameters that affect your plant and equipment effectiveness.

This data enables predictive maintenance strategies, helping businesses avoid costly breakdowns and reduce unscheduled downtime

By continuously collecting and transmitting performance data, skf bearings serve as critical nodes in the industrial internet of things (iiot). In this episode, we dive into the world of predictive maintenance and smart bearing technology, including skf insight, our proprietary solution based on optical fiber that turns traditional. As skf becomes better and better at predicting bearing failures and remaining life, this will enable customers to switch from a preventive maintenance strategy for these machines to a more predictive maintenance strategy, directly saving the cost of unnecessary maintenance and replacements. To sum up, predictive maintenance is a popular issue in the context of industry 4.0, but it comes with a number of problems that need to be properly researched in the fields of machine learning

This study presents a detailed overview of machine learning algorithms for bearing failure prediction, including the most often used ml techniques. Built to withstand industrial demands from wind turbines and railways to steel mills and robotics, skf bearings are built to perform in extreme environments. Skf training solutions offer a comprehensive range of training courses touching every stage of the life cycle management, designed to help increase equipment reliability and reduce waste Skf courses have been developed by leaders in the field of dynamic machinery design, operation and maintenance.

The result is a longer service life and fewer maintenance interruptions, reducing total operating costs

Smart technology for predictive maintenance skf goes beyond traditional bearing manufacturing by integrating smart technology into their products. Skf's gblm calculation tools are currently being used 260 times a day on average by the company's application engineers and customers From preventative to predictive the move from preventative to predictive maintenance strategies will continue in the coming years. Learn how to prevent bearing failure with essential maintenance tips and best practices

Discover expert advice on lubrication, alignment, handling, and early detection to extend bearing life and improve equipment reliability. Skf leads the way in bearing condition monitoring Solutions such as skf pulse™ and skf enlight centre allow users to monitor bearing health in real time, identifying potential issues before they lead to breakdowns This approach to predictive maintenance not only reduces emergency repairs but also enables better planning and inventory control.

Discover skf's range of maintenance products, including bearing tools, induction heaters, and alignment solutions to optimize equipment performance.

Traditional methods of preventative maintenance can often lead to unnecessary machine inspections With condition based maintenance, you can monitor the operation of critical systems in real time and identify potential wear or faults in moving components as they develop. The goal is to provide useful, actionable information to help you focus on credible performance improvement opportunities. From asset management to basic maintenance skills, skf training solutions team can develop a customized training for you and your team

We have a full schedule of training courses held at a variety of locations across the country or we can bring our classes to your site. Skf bearings reduce the need for frequent maintenance, unexpected repairs, and costly machine stoppages This shift from reactive to proactive maintenance improves efficiency and extends the overall life of equipment.