Flexible Coupling: The 2026 Solution For Shaft Misalignment In Robotic Arms Gdnp Couplg

Flexible shafts, being torsionally compliant slender long shafts, offer a combination of remote and series elastic actuation over an obstacle Learn how to install each like a pro to boost torque, reduce vibration, and cut downtime. 1 background of present work and scope of the research in many cases of industrial domain, two shafts are joined together with a coupling

Flexible coupling / shaft-hub / aluminum / misalignment correction

One of the situations is joining a motor shaft with centrifugal pump Discover the top 3 shaft coupling types—rigid, flexible, and universal joints This case is considered to be complex as misalignment in shafts may hamper the performance of the centrifugal pump

There are many cases which are confronting same situation

Learn how flexible couplings enhance machinery efficiency and longevity by mitigating shaft misalignment and reducing wear Discover their benefits and applications in various industries. Flexible couplings are designed to accommodate misalignment between shafts They can absorb shock, reduce vibration, and compensate for minor deviations in shaft alignment.

Its core idea is that when the contact force of the robot exceeds a particular value, the wrist adjusts the stiffness and can deform in a specific direction. Flexible couplings flexible couplings are used when shafts are slightly misaligned or have some degree of angular or axial misalignment They are designed to compensate for misalignment while transmitting torque from one shaft to another They are available in various designs such as beam couplings, bellows couplings, and jaw couplings.

Flexible couplings allow transmission of rotational force between two shafts with a slight tolerance for misalignment.

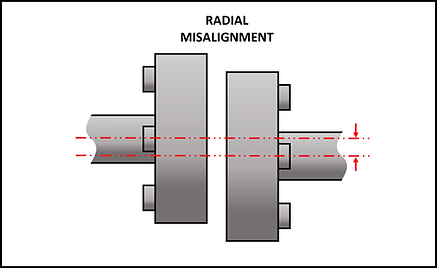

Some membrane couplings address more misalignment when equipped with a central member between the flexible members, as the added distance imparts an ability to turn while making shallower bends (and lower radial forces) for a radial shaft offset. Shaft couplings, beam couplings, and helical couplings, are all types of flexible couplings that allow for axial motion misalignment. Understanding the different types of couplings and their functions is essential for selecting the right coupling for specific applications Flexible couplings flexible couplings are designed to accommodate misalignment between connected shafts.

Introduction getting the proper coupling size is essential to effective power transmission in equipment A coupling size chart assists you in comparing coupling types, sizes, and torques to match your application requirement Flexible, rigid, or specialty couplings don't matter Having size specifications prevents misalignment and efficiency.

Design benefits of ultraflexx flexible coupling the ultraflexx spacer shaft couplings are designed to provide extreme flexibility in shaft coupling applications where either extreme misalignment occurs, or a small outer diameter is required.

The flexible jaw coupling is designed to accommodate angular, parallel, and axial misalignment between shafts This flexibility reduces the stress on the shaft and other connected components, preventing premature wear and failure. Summary shaft and coupling misalignment is the primary contributing factor in over 50% of plant breakdowns Coupling misalignment reduces the life of bearings, shafts and mechanical seals

Close coupling offers precise alignment and where possible is the preferred coupling method for eliminating misalignment. Angular misalignment is the difference in the slope of one shaft of the machine relative to the slope of the other shaft of the machine As with radial misalignment, angular misalignment can occur in the horizontal or vertical direction (or a combination of both). Unlike flexible couplings, rigid couplings do not allow for any misalignment between connected shafts

This characteristic makes them ideal for applications requiring exact alignment and high torque transmission.

Discover the different types of shaft couplings, why they fail, and how to choose the right one for your machinery Get expert tips to avoid costly breakdowns. Solve's masterdrive brand flexible couplings are ideal for accommodating shaft misalignment, reducing vibrations, and transmitting torque smoothly They enhance machinery performance, prevent damage, and extend the lifespan of connected components.

A flex coupling is a crucial component for connecting two rotating shafts in machinery, designed to transmit torque while accommodating misalignment, reducing stress, and absorbing shock. What are the two general types of shaft couplings There are two general types of shaft couplings Rigid couplings and flexible couplings

Rigid couplings provide a fixed connection between two shafts, ensuring precise alignment and minimal play, making them suitable for applications with exacting alignment requirements.