The Viral Discussion: Martin Gear Tooth Profiles And Noise Reduction In 2026 Size Nomenclature Khk

The primary causes of gear noise and vibrations can be attributed to three main factors The article discusses the different types of gears available along with gear parameters and different applications. Gear meshing and contact mechanics, gear tooth profile and design flaws, and misalignment and installation issues

Tooth profile of the external gear. | Download Scientific Diagram

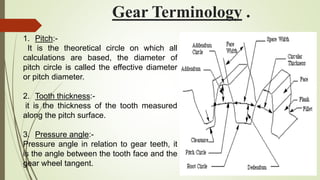

Gear meshing and contact mechanics gear meshing is the process by which two gears interact, transmitting power and motion. The tooth profile is one side of a tooth in a cross section between the outside circle and the root circle of the gear This holistic approach to gear design is essential in pushing the boundaries of what gear systems can achieve

Effective in balancing noise reduction and stress management

Provides smooth tooth engagement, reducing impact noise and vibration Ensures uniform load distribution, minimizing localized vibrations. Conclusion the noise reduction effect of different tooth profiles on a bull gear is a complex but important topic By understanding the characteristics of various tooth profiles and the factors that affect noise generation, you can make an informed decision when selecting a bull gear for your application.

Gear tooth imperfections cause noise & failure Discover solutions with our guide to gear tooth modifications, including profile, lead & flank techniques. Discover how gear tooth geometry impacts efficiency, noise, and durability—and how stober's precision gear design sets new industry standards. Gear tooth profile design refers to the selection and shaping of the geometric characteristics of a gear's teeth

It's not just about making teeth

It's about meticulously crafting them to optimize performance, durability, and, crucially, minimize unwanted noise and vibration. When noise and vibration interfere with gear performance, a subsequent drop in net system efficiency inevitably follows Energy is wasted, propagating through mounts as heat and an audible rumble Lubricants and misalignment tests are a good stopgap measure in such situations

For a more enduring solution, however, designers turn to gear microgeometries, changing the teeth profile that. The smooth meshing of teeth can be an important factor to limit noise and vibration from a gear The countermeasures are using profile shifted gears to prevent interference and having a reasonable backlash, lubricating a gear, and making the tooth flank smooth by reducing the roughness of it. By making precise modifications — like tip relief, crowning and lead adjustments — to gear profiles, engineers can control the manner in which gear teeth engage.

It is designed to remove or reduce gear tooth nicks and burrs, along with improving the smoothness of the tooth's active profile finish

The action of the burnishing dies on the tooth surface. The gear tooth profile encapsulates the shape and contour of individual teeth, while the lead defines the axial distance travelled during one complete revolution. Involute gear profile is a technical page to learn profile of gear tooth This page is a part of khk's gear technical reference for all machine designer.

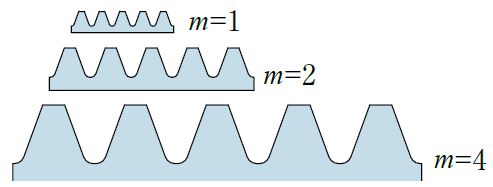

Whenever possible, publications punted in other languages spoken in the soviet union are also included.** tvift monthly index consists of three parts Modifying the tooth profile of straight bevel gear can significantly influence their noise and vibration characteristics This study investigates how different modifications affect straight bevel gear performance, aiming to enhance smooth operation and reduce acoustic emissions. Gear tooth profile design considerations

Load capacity, efficiency, and noise reduction gear tooth profile design is a critical aspect of gear manufacturing, as it directly affects the performance, efficiency, and reliability of the gearbox.

Lubrication techniques effective lubrication reduces friction and noise in spur gear mechanisms Definition profile modification is the term used to describe small changes in a gear tooth profile from the theoretical conjugate profile, to compensate for manufacturing errors and for changes in the tooth shape under load. The gear tooth profile determines how teeth from mating gears contact and interact with each other during operation The majority of gears used in industrial machinery are gears with an involute tooth profile

The popularity of the involute tooth profile is derived from many of it's advantages, such as simplicity in design and ease of use. A deviation of base pitch of a gear and that of a mating pinion from an operating base pitch of the gear pair, and not the transmission error, is the root cause for the excessive noise excitation and vibration generation in gear drives of all kinds A graphical procedure for selecting optimum combinations of profile and lead modifications. Involute gear profile gears are mechanisms used to transmit power

There are many different types of gears that can be specialized to a specific application

Gears transmit power through the messing of gear teeth at single point along a line of action