Ensuring Future Machine Shop Accuracy Through The Implementation Of The Key Chart Success Guide Docx Topic 7 Success

Get this white paper and begin implementing new best practices for quality excellence. Understand the importance of production scheduling, key planning steps, techniques, examples, and best practices to improve your manufacturing process. Quality control is critical in manufacturing to ensure products meet specifications and customer expectations

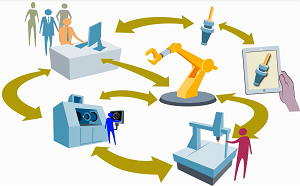

The potential for the machine shop of the future is here! - NX

Implementing robust quality control processes reduces defects, enhances efficiency, and minimizes costs Learn all you need to know about account reconciliation, including key methods, processes, and how technology can streamline reconciliation. Continuous monitoring and improvement of quality control are essential for maintaining high standards in production.

Conclusion in a cnc machine shop, the importance of a strong quality inspection and quality assurance department cannot be overstated

Machining is all about precision, quality and traceability Learn about the key elements of a machine shop's quality assurance program. Of course, every cnc machine shop will say that they highly value quality and meet quality requirements But, how do you know for sure

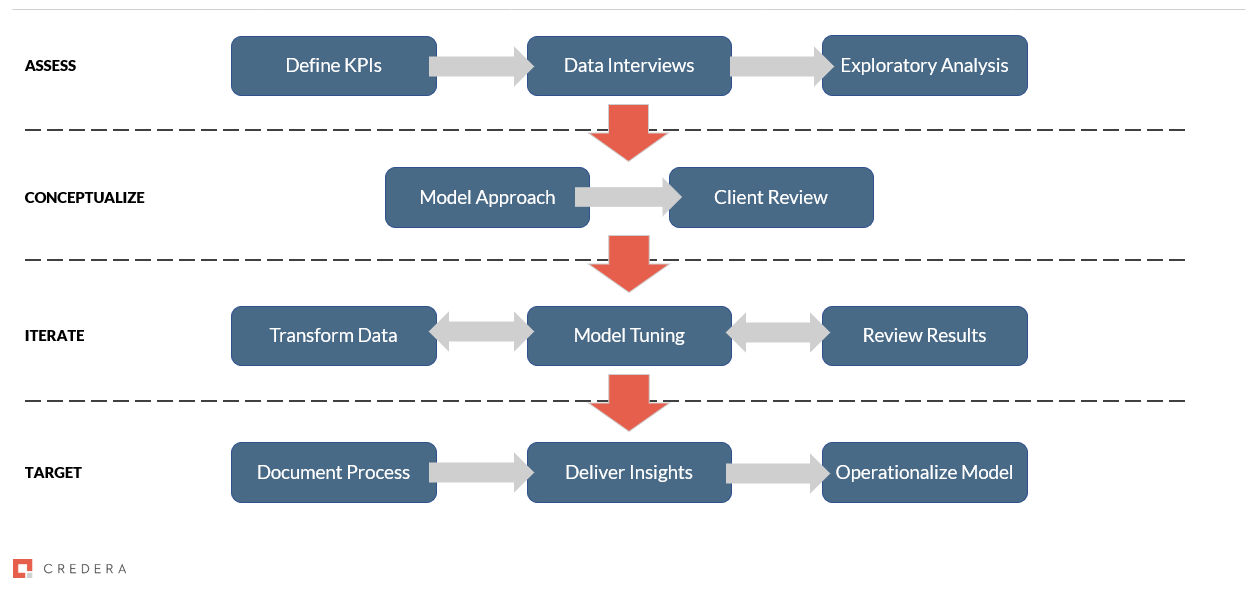

In general, a quality management system (qms) is a quality control process that helps ensure that products and services consistently meet regulatory requirements as well as the customer's requirements. Explore essential quality control techniques in cnc machining Ensuring that operators are familiar with the materials, machine settings, and tolerances required for specific parts can prevent many potential issues before they arise Conclusion ensuring quality control in cnc machining is an ongoing process that requires attention to detail, regular monitoring, and adherence to industry standards.

Machine tool calibration encapsulates a series of meticulous procedures aimed at ensuring the accuracy and reliability of machining operations

From cnc machines to lathes and grinders, each tool undergoes a rigorous calibration process to uphold stringent quality standards. Precision is key in cnc machining, precision and accuracy are not optional—they are essential Implementing best practices ensures every part performs reliably in demanding environments. It ensures traceability and allows us to address any concerns promptly

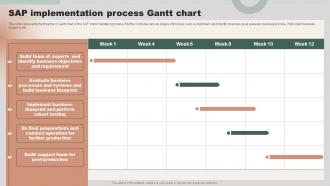

Our machine shop follows a strict calibration and maintenance schedule for all equipment and measurement devices Regular calibrations guarantee the accuracy and reliability of our machinery, ensuring consistent results. Maintenance and support are ongoing requirements in machine agnostic systems. His work and effort is largely what resulted in the formulation of what is now acknowledged as the toyota production system.

Commbuys welcome to commbuys, the only official procurement record system for the commonwealth of massachusetts

We're on a journey to advance and democratize artificial intelligence through open source and open science. Quality control in manufacturing is essential to run an efficiency and successful production business Learn all about quality control techniques and methods here. Healthcare chart audits play a pivotal role in maintaining the integrity and quality of patient care within the medical field.

We would like to show you a description here but the site won't allow us. To ensure the oee dashboard remains a valuable tool for continuous improvement, adhering to best practices for its maintenance and updating is essential This includes regular reviews of the dashboard's relevance, updating it to reflect changes in production lines or manufacturing processes, and ensuring data accuracy through periodic.