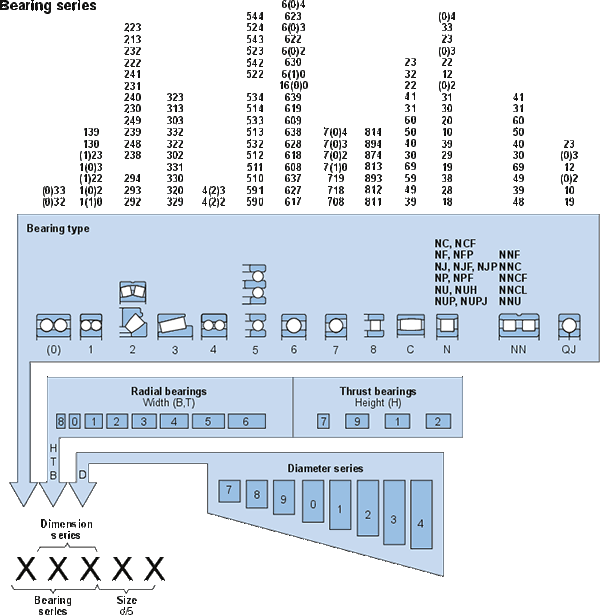

The Viral Debate: Ceramic Versus Steel Balls In The Latest Skf Bearing Models Bearg 6326 M Shandong Dali Bearg Co Ltd

Bearings might be hidden components, but the bearing material you choose dictates the performance, speed, and lifespan of your entire machine If you experience heavy spindle loads or spindle crashes, ceramic balls are more likely to cause damage (brinelling) to the bearing raceways. Whether you are upgrading a road bike or sourcing for industrial machinery, the debate often comes down to one question

skf 6301 bearing 3D Models | Page 1 | STLFinder

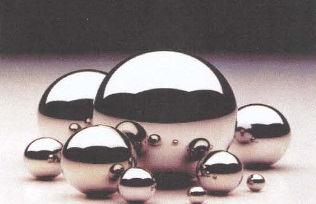

Steel bearings—which is actually better Ceramic balls have a much lower elasticity than steel balls, which is important to keep in mind when considering an upgrade to ceramic bearings Unleashing the power of hybrid bearings

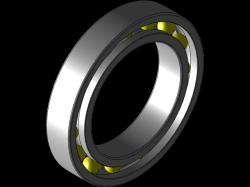

A comprehensive look at the advantages of ceramic balls vs steel balls the realm of bearing technology has witnessed a paradigm shift with the emergence of ceramic hybrid bearings, a sophisticated amalgamation of ceramic balls and traditional steel races

Even under perfect lubrication conditions, bearing steel can corrode over time, whereas ceramic bearings do not In fact, the service life of ceramic hybrid ball bearings regarding corrosion may be up to ten times longer than that of steel bearings. Lower upfront cost, but may have increased maintenance in challenging environments The purpose of this comparative analysis is to evaluate the performance differences between hybrid ceramic ball bearings and traditional steel bearings

By examining factors such as friction, weight, temperature resistance, and longevity, this analysis aims to provide insight into the advantages offered by hybrid ceramic bearings over their steel counterparts Compare ceramic vs steel bearings — discover their advantages, costs, lifespan, and best applications to choose the right bearing for your needs. Steel balls, also known as bearing balls or ball bearings, are used across a wide range of industries due to their exceptional durability, high strength, and corrosion resistance These characteristics make them indispensable in various manufacturing processes and mechanical systems

In this article, we will explore the different types of steel balls and their specific applications.

They facilitate reduced friction and enhanced mobility, which is critical for optimal performance This blog aims to provide information about the differences and distinct advantages of ceramic versus steel ball bearings, offering insights into how each type influences the efficiency, durability, and overall performance of machinery. Since the birth of the first modern ball bearing in 1869, bearing technology has continued to develop, from traditional steel bearings to modern ceramic bearings, and industrial technology has made major breakthroughs Bearings are essential key components in many machines and industrial equipment.

Hybridlager von skf kombinieren siliziumnitridkeramikkugeln mit stahlringen und bieten vorteile wie geringes gewicht, hohe verschleißfestigkeit und elektrische isolierung. How to find cad models for bearings and industrial seals, you can download a product cad model by selecting the cad tab on the applicable product page There are three ways to access a product page If you know the designation, enter it into the skf site search and from the search results, open the product page

If you don't know the product designation, navigate via the menu down to the.

The graph below shows a comparison between two steel bearings (skf and ntn) and a ceramic bearing (enduro) Initially the enduro bearing has lower friction, at around 600km of use, the ceramic bearing has worn a track into the comparatively soft steel races and the bearing friction starts to increase dramatically. Hybrid ceramic needle, spherical or tapered roller bearings why use skf hybrid ceramic bearings Electrical insulation silicon nitride insulates against electrical currents, helping prevent electrical erosion.

Inconel balls, can be made from a variety of inconel alloys Inconel alloys are a nickel base with chromium and iron Many inconel alloys were developed for specific applications Inconel balls can be made from these various alloys to satisfy the need for mechanical properties at high temperatures and corrosion resistance to certain chemicals often at elevated.

The skf bearing catalogue lists a large range of designs, variants and sizes of deep groove ball bearings

Beyond our catalogue offering, the skf explorer deep groove ball bearings are customizable to offer advantages for applications with specific performance needs. Ceramic ball bearings or steel, which one do you need and what manufacturers prefer Compare the two for your next application. Their longer service life and reduced maintenance requirements can lead to reduced energy use and fewer resources, supporting skf's dedication to a more sustainable world.

First of all, as far as friction is concerned, ceramic bearings are superior to bearing steel due to their higher roundness, light weight, hardness and smoothness This allows ceramic bearings to reduce friction and energy losses, improve equipment operating efficiency, and maintain operating efficiency for a longer period of time. Check out our interactive digital publication, powered by dirxion, the ultimate flip book platform The user interface makes reading and searching easy.

Skf's ceramic community, comprising researchers, designers, developers and production staff, is now tasked with reducing cost by exploring all process improvements and innovations across the entire value chain.