Efficiency Stats: How Skf Bearing Company Is Reducing Global Energy Loss Consulting Inc Linkedin

Skf, a global industrial machinery manufacturer, has positioned itself among these organisations by prioritising energy waste reduction and environmental impact improvements. Skf participated in discussions and events focused on accelerating the transition to renewable energy, reducing carbon emissi Skf participated in discussions and events focused on accelerating the transition to renewable energy, reducing carbon emissions, and promoting sustainable practices within the industry

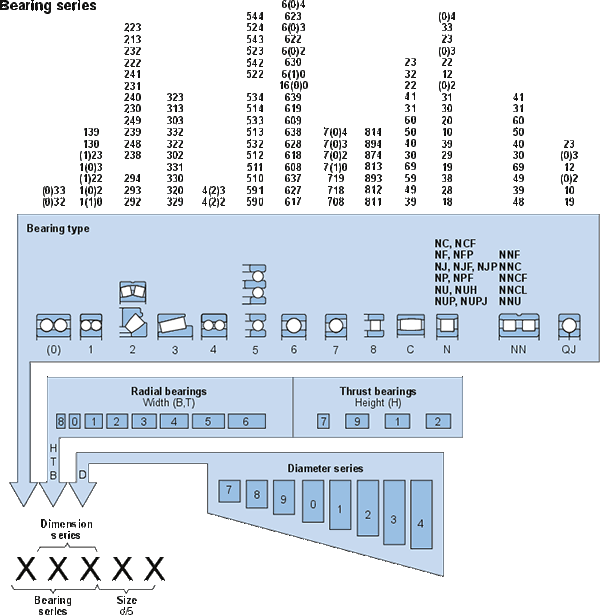

SKF bearing cross reference, interchange | Coolen Bearings

Skf, a swedish manufacturer of bearings and seals, announced the company achieved a 59% reduction in emissions in 2024 Oup in partnership with the united nations general assembly Details were provided in its annual and sustainability report that highlights the progress towards skf's 2030 decarbonization target of a 95% reduction in scope 1 and 2 emissions from a 2019 baseline.

By only replacing bearings when truly needed, companies reduce waste and streamline their environmental impact

Applications across sustainable industries skf bearings are empowering the shift toward green technologies across sectors The global bearing market is generally defined as the worldwide sales of rolling bearings, comprising ball and roller bearing assemblies of various designs Skf estimates that the global bearing market grew by 6% to 9% in 2022. For these sites, the company has invested in energy efficient technologies including heat pumps and advanced chillers, bringing energy savings despite an increase in production

The nine total decarbonised facilities represent almost 20% of skf's baseline manufacturing emissions, allowing it to reduce its overall carbon footprint. Reducing energy consumption friction is the hidden enemy of efficiency Skf bearings are designed to minimize energy loss by reducing friction to the lowest possible level This translates directly into lower energy consumption, smaller carbon footprints, and cost savings for industries committed to sustainability without sacrificing performance.

Intense development efforts within skf have resulted in the launch of a new family of bearings that can deliver significantly lower energy consumption than traditional bearings

The new bearing family, called energy efficient bearings, entered manufacturing during 2007. The installation of chillers with skf magnetic bearings in our factory in xinchang, china, saves 60 gwh over the chiller life span corresponding to more than 35.000 tons of avoided co2e emissions. The skf sealed e2 deep groove ball bearing is part of the skf beyondzero product portfolio Discover skf's insights on bearing friction, power loss, and starting torque for optimal performance in various applications.

Skf has developed a new family of bearings that reduce energy consumption by at least 30 percent compared with standard iso products Alternatively, you can use skf product select to perform this calculation For additional information on the calculations → the skf model for calculating the frictional moment For specific bearing types and key applications, the goal is lower friction bearings designed for operating energy efficiency.

By reducing energy consumption to overcome equipment friction, energy efficiency can be directly increased, and maintenance and repair efficiency can be improved

In rotating equipment, bearings play a critical role, and in order to achieve optimal performance and high bearing efficiency, lubrication must be performed appropriately. Learn about bearing friction, power loss, and starting torque for optimal rolling bearing performance at various operating temperatures and speeds. Reduced friction means increased grease life and service life optimized to reduce frictional losses and operating temperature in the bearing, capped skf energy efficient deep groove ball bearings can last at least twice as long as comparable skf explorer bearings in many applications This means that in applications where conventional bearings fail and are replaced, the longer service life of.

The company has developed a new performance class of bearings, termed the skf energy efficient (e2), that reduces frictional losses in the bearing by at least 30% when compared with the company's. This is a major part of their operational cost efficiency Drawing on skf competencies in mechatronics, bearing design, composites, and metallurgy, skf engineers help designers of aircrafts reduce the weight of several systems and subsystems, resulting in increased fuel economy. Global leaders trust skf bearings because they deliver reliability, efficiency, and a path toward greener operations

By reducing energy use, extending machine life, and enabling smarter operations, skf is more than a bearing supplier—it is a strategic partner in building a sustainable industrial future.