Defining The Future Of High-speed Industrial Motion Using Advanced Jaw Coupling Gr Curved Bonna Flex

In mechanical engineering, a jaw coupling is a type of general purpose power transmission coupling that also can be used in motion control (servo) applications The fit of the teeth in a gear coupling allows for misalignment, but the degree of angular misalignment compensation depends on the contour of the gear teeth and the clearance between them. It is designed to transmit torque (by connecting two shafts) while damping system vibrations and accommodating misalignment, which protects other components from damage

Rotex GG25 2-3/8" Flexible Jaw Coupling Hub | Bullseye Industrial Sales

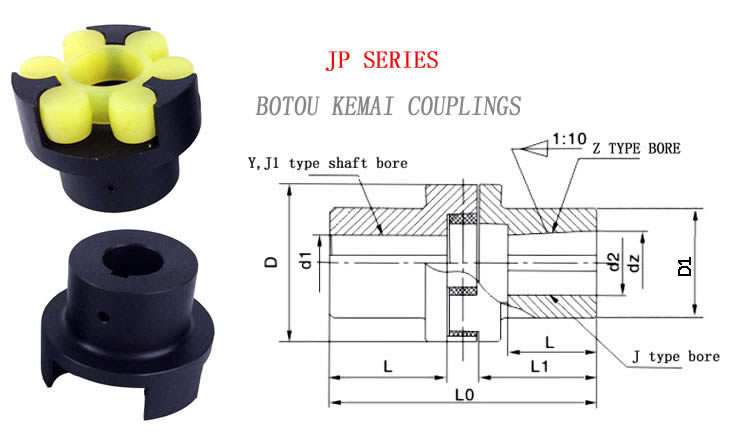

Jaw couplings are composed of three parts This design is characterised by two hubs, each having two or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. The high speed coupling market size was valued at 2,068.3 usd million in 2024

The high speed coupling market is expected to grow from 2,151 usd million in 2025 to 3,200 usd million by 2035.

Designed for use with servo motors, standard motors, and stepping motors, these jaw type (bushing) flexible couplings optimize operation and extend equipment lifespan in demanding industrial environments. Jaw couplings connect the shaft of a motor, or moveable machine to the shaft on a stationary machine Straight jaw couplings are suitable for most industrial applications, while curved jaw couplings are suitable where zero backlash is required, such as stepper or servo motor applications where precise motion control. This pushes manufacturers to innovate in areas such as

Improved forging techniques for consistent jaw alignment Integration of ergonomic handle design with adjustable mechanisms. Designed for durability and efficiency, this coupling comes in several specialized variants to meet diverse operational demands Understanding the different types helps in.

In this investigation, a cpg integrated with a bistable mechanism (bm) is developed for gripping of objects.

We would like to show you a description here but the site won't allow us. In order to keep the millennial generation analytically meaningful, and to begin looking at what might be unique about the next cohort, pew research center decided a year ago to use 1996 as the last birth year for millennials for our future work. Jaw coupling is a material flexing coupling that transmits torque through the compression of an elastomeric spider insert placed between two intermeshing jaws. Examine the roles and functions of shaft couplings

Browse various types of shaft couplings including driveshafts, motor couplings, and flexible shaft couplings. Jaw coupling computer drawing of a curved jaw coupling in mechanical engineering, a jaw coupling is a type of general purpose power transmission coupling that also can be used in motion control (servo) applications. Industrial coupling market outlook from 2025 to 2035 the global market for industrial coupling is projected to achieve steady growth from 2025 to 2035, driven by increasing demand for power transmission equipment with improved performance, increasing industrial automation, and transformation in heavy industries. Spiders are key to jaw coupling performance one of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling