Defining The Future Of Zero-emission Transport Solutions With Skf Bearings

For many years, we have applied the greenhouse gas reporting protocol to define, report, and fol Skf offers a range of services to optimize bearing performance and reliability for various industries. Since 1907, skf has been making some of the world's most innovative bearings, seals, lubrication systems, condition monitoring solutions, and services to reduce friction

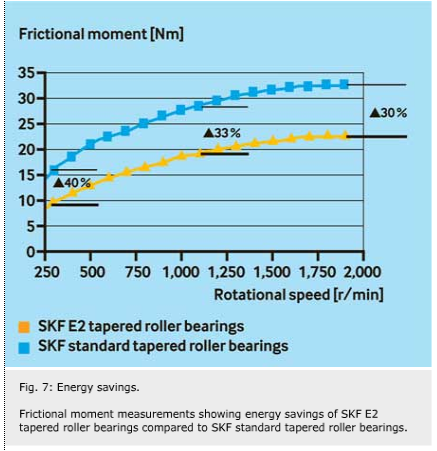

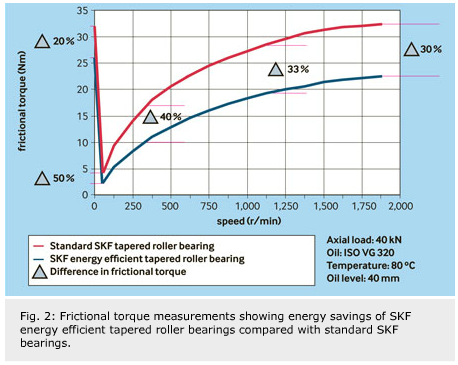

SKF Explorer and SKF Energy Efficient bearings provide sustainable

Less friction means more energy saved and by reducing it, we make industry smarter, more competitive, and more energy efficient, building a more sustainable future where we can all do more with less Explore skf's comprehensive range of rolling bearings, offering innovative solutions for various industries to enhance equipment performance and reliability. Skf's spherical roller bearing prototype signaled a milestone in green steel bearings manufacturing

Skf also works with customers to help decarbonize their value chains, offering solutions that align with global environmental standards and esg goals.

In 2000, we were one of the first companies to start to report and set climate targets Acting on energy and material efficiency improvements and by switching to renewable energy, skf is targeting decarbonizing its operations by 2030 and reaching net zero emissions throughout the value chain, by 2050. To reach net zero globally, companies are urged to actively reduce their emissions Skf is using renewable energy to electrify both heating and heat treatment processes

They are also optimising material and energy efficiency in every manufacturing step. These solutions reflect skf's mission to support industrial decarbonisation while improving reliability and lowering total cost of ownership across critical sectors At cop30 in belém, brazil, skf will showcase scalable clean technologies and circular solutions to accelerate industrial decarbonization, reaffirming its commitment to innovation, circularity, and responsible growth Accelerating industrial decarbonization skf's remanufacturing initiative exemplifies how clean technologies and circular solutions can accelerate industrial decarbonization

Remanufactured bearings perform like new—at a lower cost, with shorter lead times, and a significantly reduced manufacturing co₂ footprint.

In a new collaboration, skf has chosen to source greensteel climate+ from swiss steel group for bars and wires produced in emea. At skf, we have a long history of working with industrial sustainability It is an integral part of what we do every day And we strive to create engagement throughout the business, not only by implementing sustainability on a strategic level, but also by encouraging the ideas and grass root projects initiated by our people around the world

But, to continue on the journey to enable rotation. The tool also offers the opportunity to engage with skf's expert application engineers, who can provide a detailed view of the specific carbon emissions for the bearings and how the customer's application can be optimised to reduce energy consumption and corresponding emissions in the future Johan lannering, head of sustainability at skf. Conclusion skf bearings are built for more than today—they are built for the future

By uniting strength, innovation, and sustainability, skf ensures industries worldwide can meet evolving demands with confidence

Bearings have enabled the growth of industries, revolutionized transport, and enhanced overall quality of human life Since the start in 1907, our focus has remained the same Creating an everyday life with less friction To do this, we have developed bearings suitable for a wide variety of applications and conditions.

Skf has signed a letter of intent with cake, the swedish maker of premium, lightweight, electric motorcycles, to explore how it can incorporate bearings produced with the lowest possible carbon emissions. The fight against global warming is high on the agenda of many big companies, including skf Arctic15 is the first innovative steel for aerospace applications in over 30 years Engineered to withstand higher loads, speeds, and harsh conditions, it performs far beyond the limits of current aerospace steels

Advanced bearing solutions that enable more efficient aerospace engines—delivering significant reduction in fuel consumption.

Savings in the bag remanufactured skf bearings are cutting costs and carbon emissions at the mondi štĕtí paper mill. Sealing can significantly prolong bearing service life by keeping lubricant in the bearing and contaminants out Ball and roller bearing units are supplied with seals When using housings with bearings, or split bearing units, you can select from a wide assortment of skf seals

At shaft end positions, consider using an end cover to improve the sealing (fig In addition, end covers protect. Discover skf's range of services designed to enhance equipment performance, optimize maintenance, and ensure reliability across various industries.