Defining The Future Of Secure Industrial Power Delivery With Evolved Keyway Types Sturdy Wholesale At Reasonable Prices Alibaba Com

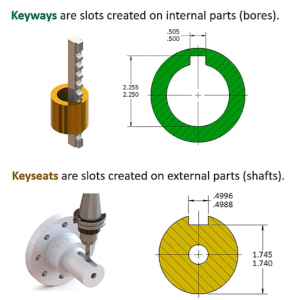

Introduction to keyways keyways are essential features in mechanical design that facilitate the secure engagement of shafts and hubs in machinery Types, applications, materials, and selection tips to improve mechanical performance and safety. A keyway is a slot or groove cut into a shaft or hub, into which a key is inserted to prevent relative rotation

Keyway Size Chart | Keyway Dimensions, Tolerances, Types, Design

This article will explain the various types of keyways, their applications, and their significance in machining A comprehensive guide to machine keys Shaft key selection and keyway design should consider key types, correct fit, key material, shaft material, load, fatigue & safety factors

To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint.

This pa note will explain the uses of keys and keyways in pulleys and bushings, and present current industry standards for key and keyway component sizing. This also involves updating feeder, substation, and distribution system design practices, and utilizing new technologies and equipment to create a flexible and resilient grid that is ready for the new requirements set by der and electric transportation adoption, such as bidirectional and variable power flows through service and substation. Electric power research institute ceids is pursuing a defining set of major power delivery system science and technology infrastructure requirements for the future. This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications

It also highlights the importance of keyway machining in maintaining the integrity and performance of mechanical systems, emphasizing the relationship between keyway design and. Impact for distribution system innovation in the rapidly changing power system, complexities and dependencies will increase, and it is essential to analyse and monitor the development of the security of supply, to ensure a secure and resilient power system. Precision keyway machining for secure assemblies in mechanical systems, proper alignment and secure assembly are crucial to ensure efficiency and longevity One of the most effective ways to achieve this is through keyways—machined slots in shafts and components that allow for the insertion of keys, ensuring a firm connection with couplings, gears, and pulleys

Here are some key developments

The future of power distribution one of the most significant advancements in recent years has been the development of smart grids It other words, the torsional strength of the shaft is reduced. A keyway is a slot or groove in a shaft or hub in which a key is inserted to secure two components together and prevent relative motion between them Keyways are commonly used in mechanical applications to transmit torque from a rotating shaft to a component such as a gear or pulley.

Some open keyways require manufacturer approval before a distributor can supply their products but, besides that, an open keyway can be sold right off the shelf to any customer who walks in For example, a schlage c keyway is an open keyway that is available from many key and lock distributors. In the world of mechanical engineering, shaft keyways are essential components for powering your machines But with so many types to choose from, it can be hard to know which one is right for you

We've compiled a comprehensive guide breaking down all the major types of shaft keyways and their uses

Find your perfect fit today! What is the cost difference between keyway types The cost of keyway installation can vary significantly based on the type chosen, with standard keyways generally being the most economical and dowel keyways typically costing more due to the added materials and labor involved. ( types of shaft keys ) these keys are used to secure a member with the machine shaft which can fits with the machine shaft which can fits with the keyway in member and they are concave so that they can grip the shaft with friction

As compared with sunk keys, these keys cannot sunk in shaft and hub, they can sunk in the hub only. Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. Choose from our selection of keyways, including machine keys, rounded machine keys, and more Same and next day delivery.

Principle applications of the new package are expected in industrial drives, traction, renewable energy and power transmission applications.

The method of mechanical component connection, keyed vs Keyless, has a significant impact on performance Understanding the distinctions between the two connection types can help engineers choose the best option for their systems.