Printing Firms Debate The Durability Of Flex Couplings Vs Steel O Octaforce

Although not as flexible as elastomeric couplings, gear couplings can accommodate slight misalignments, particularly angular and axial misalignments. Look for performance features that include a high double rub count (dr) count and pill resistance for ultimate durability Processes for consideration during flex coupling production are machining, additive manufacturing, forging, casting, injection molding, welding, and bonding

Jaw Flex Couplings, Torsionally Soft Couplings, Pin Bush Couplings

Common materials for flex couplings steel alloys As mentioned earlier, steel armor is generally less expensive than polyethylene armor, which can make it a more attractive option for those on a tight budget. Common materials for flex couplings due to their high strength and resistance to wear.

Flexible couplings and rigid couplings each have their distinct advantages and applications in power transmission systems

By understanding the differences between these two options and carefully assessing your specific requirements and operating conditions, you can make an informed decision to choose the right coupling for your application. When engineers consider connecting and transmitting power in mechanical systems, couplings are often the key components that they prioritize With a wide variety of coupling options available, this article will compare two of the most common types Rigid couplings and flexible couplings, across three key aspects

Comparison of performance and function rigid couplings January 28, 2025 flexible couplings couple or connect rotating members such as motors and drive shafts while allowing misalignment in either angular or parallel offset orientation Rigid and flexible couplings transfer torque Learn their differences, misalignment tolerances, and ideal use cases.

Discover the differences between flexible and rigid couplings, including their applications, torque transmission capabilities, and maintenance requirements, to select the optimal solution for industrial machinery.

These materials provide durability and resistance to corrosion, which is crucial for the longevity of printing press components. Discover the advantages and disadvantages of different coupling materials for your engineering needs From metal's durability to rubber's flexibility and plastic's corrosion resistance, find the right balance of strength, cost, and performance for your specific application. So, we thought it would be best to lay out the steel vs aluminum conversation clearly to provide more clarity on their properties and what to expect from them.

Type t63 stopping or service brake applications size The coupling brake rating must equal or exceed the application requirements Determine the required coupling size by comparing the application loads (from steps a, b and c below) to the coupling brake rating listed on page 28 Use the highest torque value calculated to determine the coupling size

For the selected caliper brake and disc.

So, what are the differences between aluminum vs brass vs stainless steel hose fittings Aluminum hose fitting is more lightweight than brass and stainless steel Stainless steel serves the most durability among the three metals Also, stainless steel hose fittings are extremely resistant to water corrosion, galvanic corrosion, and pressure.

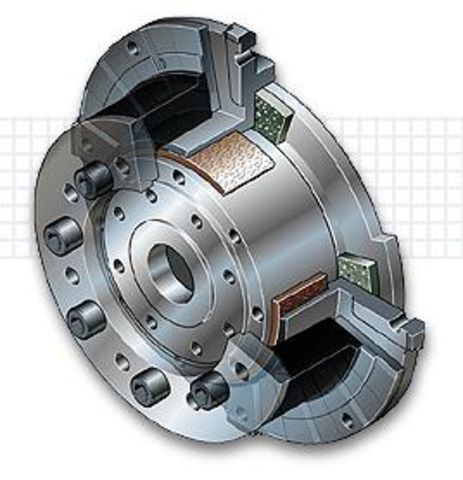

The basic flex coupling consists of two hubs, a spacer and two flexible discs The flex disc is an assembly of thin metal laminations In figure shown below, flex disc holes a & c are bolted to the hub and holes b & d are bolted to the spacer Torque is transmitted in direct tensions from a to b and from c to d through the flex disc

Misalignment is taken through bending in the link between.

Flange adaptors are tougher than couplings in terms of durability Properly selected and installed felxible couplings maintain the continuity of the pipe system, retain the line contents under internal pressure and prevent infiltration under vacuum. Compare cast iron vs steel with damping, wear resistance, strength and toughness—discover the ideal material for engines, structures, cookware, and beyond. Discover the essential guide to coupling, including their types, purposes, materials, and key design considerations.

Cost considerations in the durability debate while durability is a crucial factor in choosing body armor, cost is also an important consideration for many individuals and organizations