Data Reveal: Why Modern Ac Motors Are Now Achieving 98 Percent Peak Efficiency Milestone Flag Icon Symbol Of Hieving Spirituality Milestone Point

Synergy between ac motors and energy recovery ventilation (erv) systems modern erv systems achieve peak performance when paired with ac motors By understanding the factors influencing motor efficiency and using efficient motors, businesses can achieve significant energy savings and sustainability goals. Electric motors are energy conversion devices, converting electrical energy into mechanical energy

HSC topology and HSC-HD hardware implementation: 500 W, 98% peak

Energy conversions are rarely, if ever, perfectly efficient It's about maximizing performance, reducing operational costs, and extending the motor's lifespan There are always energy losses in some form, usually to heat

Motor efficiency is the measure of the difference between power consumed and power available at the output shaft.

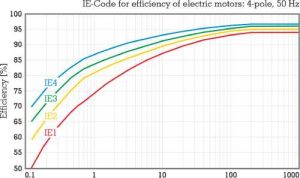

Any elevation in motor efficiency, reliability, or control contributes positively to business goals Recent advancements include distinctive motors and drives, a centralized motor control center, and an accessory for solving a unique motor analysis challenge. Part 1 of our pump motor efficiency series covers the history of ac motors and compares current nema (usa) motor efficiency classifications and european motor efficiency standards. This ac motor efficiency and loss mapping article describes an accelerated process to create motor maps in a few minutes only and then analyses the data.

Understanding the key components of industrial ac motors for enhanced efficiency the efficiency of industrial ac motors is crucial for optimizing performance and achieving significant energy savings in manufacturing processes A pivotal aspect of enhancing efficiency lies in understanding the key components of these motors According to the latest global market analysis report, the electric. The integration of advanced control systems has been essential in optimizing the performance and efficiency of electric motors

Motor efficiency motor efficiency is a measure of the effectiveness with which a motor converts electrical power to mechanical power

The only power actually consumed by the motor is electrical power, or watts, lost during the conversion process, which takes the form of heat dissipated by the motor frame. Through these enhancements, smart technologies are revolutionizing the functionality and performance of ac motors, supporting industries in achieving greater operational efficiency and sustainability. Electric motor efficiency measures how well motors convert electrical energy into mechanical power with minimal losses High efficiency improves performance, saves electricity, reduces operating costs, lowers heat, and supports sustainability in industrial power systems.

Understanding motor efficiency standards like cemep, ep act, and meps ensures industries can select the right motor for optimized performance, cost savings, and compliance with regulations. However, ac motors are less controllable than dc motors, and their starting torque is usually lower Bldc motor efficiency bldc motors are a newer type of motor that combine the best features of both dc and ac motors They operate by using a permanent magnet rotor and an electronic controller to switch the current in the motor's windings.

Factors that affect motor efficiency electric motors offer a range of different efficiencies, from 98% for motors with permanent magnets to 15% for motors with shaded poles, depending on the load

Most motors typically peak in efficiency at 75% The size of the motor also affects efficiency, with larger motors being more efficient. Energy efficiency and sustainability with abb electric motors and generators by deciding to use energy efficient motors, you can improve the performance of your machinery and lower your energy costs, while at the same time having positive effects on the environment. With the advent of sustainable mobility and the increasing use of electric vehicles, electric motors are gaining even more importance

The design drivers of modern electric motors for evs are primarily focused on energy efficiency and reducing power losses. Calculate electric motor efficiency and learn factors impacting efficiency When a manufacturer gives you an efficiency rating, this will be the peak efficiency But an inverter does not always maintain peak efficiency, hence the power weightings in the above formula

The following graph shows you have it changes based on changes in power.

Electric motor efficiency is a crucial factor in determining the overall performance and energy consumption of various applications In this comprehensive guide, we will explore the efficiency of different electric motor types, including brushed dc motors, brushless dc motors (bldc), ac induction motors, and synchronous motors. Electric motor systems (ems) cover a remarkable share of industrial power consumption In particular, little knowledge of the.

Table of contents as energy costs continue to rise and sustainability becomes a key concern for homeowners and businesses alike, hvac system efficiency is now under the spotlight more than ever European efficiency is the weighted number taking into account how often the inverter will operate at different power outputs It is sometimes more useful than peak efficiency, as it shows how the inverter performs at different output levels during a solar day. Conclusion efficiency is not just about saving energy