Deep Dive Into Power Transmission Strategy: Optimizing Every Belt Pulley System Empi Vw Serpentine Polished Www Drivepure Com

Reach us and discover how our products can help improve the precision and durability of your power transmission systems! Belt drive pulleys play an essential part in increasing equipment efficiency by offering a straightforward means of transmitting power that reduces energy loss, wear on machinery. These drives provide significant advantages, including reduced slippage, higher power handling, and improved durability due to better grip and alignment.

PPT - Optimizing Power System Reliability PowerPoint Presentation, free

With a pulley (or sheave) directly connected to the power source shaft and the machinery shaft, a v belt can then be employed to connect the power source to the machinery requiring rotation They are consisting of belts and pulleys working together, belt drive systems transport mechanical power between various parts of a machine Not only will this result in the transmission of power, but it can also facilitate the transmission of power over distance.

Discover advanced techniques for designing and optimizing pulleys and belt drives, including simulation, analysis, and testing methods.

Power transmission devices typically include belts, gears or roller chains From a system design standpoint, the drive system selection can significantly impact overall system eficiency and performance Saving a unit of energy in the belt drive operation means one less unit of energy for the motor to deliver, reducing motor output. Forces acting on a fixed pulley in the article how does a belt drive work

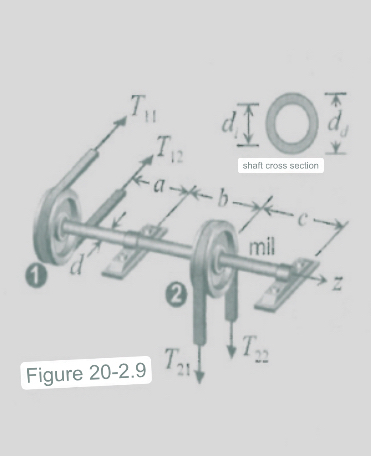

It has already been explained that the power transmission of belt drives is due to frictional forces between belt and pulley (exception This section will discuss the physical principles in more detail In order to better understand the forces acting on a belt drive, a fixed pulley is first considered. Belts and pulleys are important components for efficient power transmission in various industries

Whether in automotive systems, agricultural equipment, or industrial machinery, they maintain smooth and reliable operation

Here are the essential details of these components, how they. The primary function of a belt pulley system is to facilitate the transfer of power from one rotating shaft to another This is achieved by the rotation of the driving pulley, which, through the belt, transmits motion to the driven pulley In part two of our power transmission guide, learn about the different types of industrial belts, including their applications and best practices.

Introduction in belt drives, power is transmitted between at least two pulleys by a belt One pulley drives the belt (driving pulley) and the other pulley is driven by the belt (driven pulley) In belt drives, the speed is often reduced, so that in these cases the smaller of the two pulleys is the driving pulley Operating principle of a belt drive power transmission with belt drives.

What is a pulley simple machine

How does it make work easier Learn its types, examples, mechanical advantage, uses, & applications. Do you need a new v belt pulley but have no idea where to look Stop searching because here is it

Whether you're an experienced pro or just getting started, you'll find all the information you need here regarding v belt pulleys We've got you covered, from learning about the various options to picking the best one for your needs and ensuring its proper upkeep Let's take a deep dive into the. The system consists of two main components

The belt, which is a flexible loop made of a material like rubber, and the pulleys, which are wheels with grooves that the belt wraps around

As one pulley rotates, it drives the belt, which in turn drives the other pulley, transferring motion and power from one shaft to another. Power transmission of belt drive this circumferential force f c causes different forces on the two belt sections and a tight side and a slack side will form. In this post i will explain about 10 belt and pulley mechanism examples Open belt, cross belt, change speed belt,.how it work?

Serve cities including manila, cebu city, davao city, quezon city & more. Add the engineering toolbox extension to your sketchup make. V belt pulleys minimize noise pollution by ensuring that the belt engages smoothly with the pulley, avoiding the clatter and vibration typically associated with other types of power transmission systems like chain drives. In conclusion many that want a comprehensive understanding of power transmission through belt drives will benefit from this article

This article contains all of the necessary details about belt drives

Belt drives are preferred in most factories and mills that require efficient material shifting or load carrying. How often should i inspect my belt drive pulleys Belt drive systems are integral parts of many industrial machinery pieces