Analyzing The Strategic Precision Machining Behind Every High-end Shaft Collars Fledon

This article explores the key techniques, challenges, and advancements in shaft machining within the realm of precision manufacturing. Same and next day delivery. Discover shaft machining with hplmachining

SHAFT END MACHINING

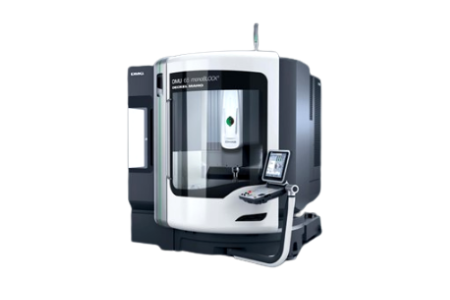

Learn expert techniques, services, and benefits—explore precision solutions today! In this article, we will delve deep into the. The precision of the spindle core is extremely high, and it is very di cult to obtain directly by traditional computer numerical control (cnc) machine tools but is mostly obtained by manual grinding, whose machining e ciency is greatly.

Components, process types, and future market outlook precision machining is a manufacturing process that creates high precision components with desirable surface finishes to tight design tolerances

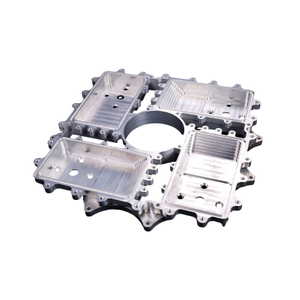

As a subtractive process, it transforms workpieces into finished parts or products by precisely removing material through a variety of operations, such as turning, drilling, milling, and grinding. Types, materials, finishes, processes for high performance and reliability in aerospace, automotive, and industrial uses. A shaft collar is a simple but important mechanical component used to locate, position, or secure parts on a shaft In many industrial systems, shaft collars

This means that every huijue drive shaft, motor shaft, or other machined product is not merely a precision mechanical part, but an intelligent carrier embodying the global industrial language, capable of precisely communicating with drive systems anywhere in the world. 80% of our team members are skilled technicians. Here you will learn about 10 types of precision shaft machining processes Also you will know more their applications, characteristics and so on.

Round bore shaft collars round bore shaft collars shaft collars assist in the three main functions of 1) holding components in place, 2) locating or positioning components on a shaft or 3) creating an attachment between the shaft and another component

They are easy to install, have broad versatility, and are highly customizable to your needs. Discover how shaft collars can contribute to shaft applications Learn about their important design considerations and how different types of shaft collars work. Uses for shaft collars as mentioned, shaft collars are used for locating components, mechanical stops and bearing faces on a shaft

Here are some examples that might inspire your next project Sprockets, gears and other machine components on the shaft can be located with a shaft collar. At stafford manufacturing corp., we have the expertise and the product offerings to fulfill virtually any shaft collar need Read on to learn more about stafford manufacturing, our customization capabilities, what to look for when choosing a shaft collar for your application, and the wide range of shaft collars we offer our customers.

Shaft collars, though seemingly unassuming, are integral mechanical devices designed to grip and secure rotating shafts firmly

The seemingly straightforward nature of shaft collars belies their significant impact on various industries They serve multiple functions, including maintaining shaft position, preventing slippage, and damping vibrations