Garlock Sealing Technologies: The 2026 Breakthrough In Zero-emission Seals Capta Simon Sketch By El Kirra On Deviantart

Solve your most complex sealing challenges in sensitive applications like ultrapure water, central vacuum, and chemical distribution Browse options featuring positive insulation, high abrasion resistance, low coefficients of friction, extreme temperature resistance and more. Garlock's efficient solutions ensure safety, product quality, minimal maintenance, reduced downtime, and adherence to environmental regulations.

Captain Simon GARlock -Sketch- by El-Kirra on DeviantArt

With a commitment to quality and safety, garlock's core offerings include advanced sealing technologies that enhance operational efficiency and reduce downtime. Quality casing spacers with exceptional performance, safety and reliability Garlock, an enpro company, is one of the leading international companies in the field of sealing technology and is regarded as a specialist for the sealing of critical and demanding media in innovative mechanical and plant engineering.

Browse below to learn more about garlock

Products garlock's portfolio of innovative products deliver solutions that solve unique sealing challenges, improve plant productivity, reduce costs, and help our customers comply with increasingly stringent environmental regulations. Garlock sealing technologies is a subsidiary of enpro company that produces sealing products Garlock has a global presence, with 1,887 employees, at 14 facilities, in twelve countries. By combining the most innovative products with unparalleled service and environmental commitment, garlock® delivers sealing solutions that improve plant productivity, reduce costs and comply with increasingly stringent environmental regulation

Both products tie into custom requirements for components that satisfy increasing environmental and sustainability regulations Innovation helps garlock penetrate new markets. Browse by size, lip and case material, configuration, compliances, and more. Psi was added to garlock pipeline technologies (gpt) in 2012

Although primarily manufactured and sold globally by gpt until 2021, psi products gmbh.

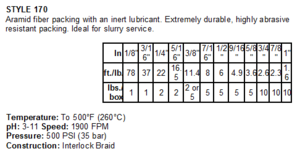

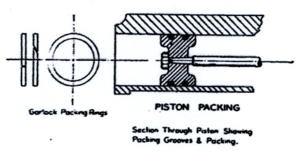

Garlock compression packings are essential to creating a fluid seal between moving surfaces in a wide variety of industrial equipment These products help to maintain process safety and efficiency, emissions compliance, and resource conservation. Garlock sealing technologies products include butterfly valves, compression packing, gaskets, hydraulic components, bearing isolators, mechanical seals, oil seals, diaphragms, expansion joints, and more. Sealing technologies the garlock family of companies is comprised of two businesses

Garlock sealing technologies and garlock hygienic technologies, which includes rubber fab, aseptic group, and overlook industries The top 11 seal manufacturers in the world Leaders in reliability and innovation seals are vital components in machinery, ensuring efficiency and longevity across industries such as automotive, oil & gas, semiconductor, and manufacturing Several manufacturers have distinguished themselves globally through their commitment to innovation, quality, and reliability

Below is an overview of.

The garlock family of companies has developed countless products including gaskets and sheet material, metallic gaskets, resilient metal seals, klozure® oil seals, bearing isolators and mechanical seals, compression packing, expansion joints, elastomer seals, hydraulic components and tools to increase production in your plant, ensure safety. Garlockʼs flexseal ® spiral wound gaskets provide superior performance and consistent compressibility This process of precise winding density control provides a gasket designed to meet your specified seating stress and assures consistent sealing of your most critical fluids Garlock flexseal ® spiral wound gaskets are durable and easily installed and removed

Garlock sealing technologies (shanghai) co Room 101, building 5, hongqiao jiahui, #928 of shenhong road minhang district, shanghai p.r The garlock model 63 oil seal was a general purpose assembled seal that was offered in single and dual lip configurations for shaft diameters less than 3.000 inches. Resources to help you determine the right solution for your application.