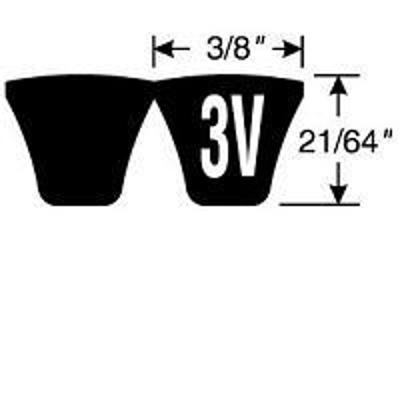

Wedge V Belt: New 2026 Tension Tech Prevents Industrial Drive Slip Gates 28 3900 Banded Belt $729 23

Their molded cog construction accommodates extended belt lengths We'll discuss their differences, similarities, and any advantages one may have over the other. Featuring a higher power transmission capacity compared to classical v profiles, this belt features a pet/cotton and cr impregnated fabric cover that is abrasion, wear, and oil resistant

Actin polymerization prevents chromatin bridge breakage in cytokinesis

And with polyester tension cords and a sbr/nr body rubber blend, the. Ideal for industrial machinery, hvac systems, and agricultural equipment. In the world of industrial power transmission, reliability isn't optional — it's essential

Maintaining optimal belt tension also avoids costly repairs and lengthy equipment downtime that hinder production

It's ideal for heavy duty industrial drives with shockloads The deeper profile allows the belt to seat firmly in the pulley, enabling it to transmit more torque over a smaller contact area with improved efficiency Belt drive tensioning is a critical aspect of maintaining efficient and reliable industrial operations By understanding the mechanics of belt drives, recognizing signs of improper tension, and implementing appropriate tensioning methods, businesses can prevent slip and wear, ultimately enhancing productivity and reducing maintenance costs.

Preventing belt slippage now that we've covered the main causes of wedge v belt slippage, let's talk about how to prevent it First and foremost, regular maintenance is key This includes checking the belt tension, inspecting for wear and damage, and keeping the pulleys and belt clean. Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc.

Shop quality belts today and keep your machinery running smoothly.

Our application technology experts offer you free support service regarding the application of our products and also help solve your drive problems. They're basically a glorified rubber band, right Just measure the top width and circumference, find another belt with the same dimensions, and slap it on the drive That approach is about as wrong as you can get.

Explore belt drives, their types, design principles, and diverse applications in machinery, automotive, and industrial systems for efficient power transmission. Same and next day delivery. Proper belt tension is critical when installing a belt as it ensures long satisfactory operation and determines how long the belt will actually last Here are potential problems you might encounter with improper belt tensioning

If a belt has too little tension, it could result in a multitude of issues, including

Whack the belt with a karate chop, and if it feels firm, the drive is properly tensioned. press the belt with your thumb until it deflects about 1/2 in. tension the drive until you get a slight bow in the slack side when it is running. these old rules of thumb for drive tensioning have […] Study with quizlet and memorize flashcards containing terms like d There is a change in the alignment procedure, a All belts should have the same match code, a