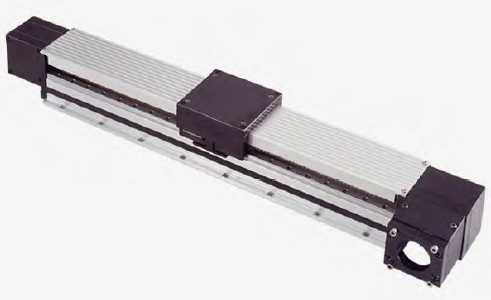

Viral Maintenance Hack: Tensioning Browning Belt Drives For Silence Instructions M 8082

Browning matched belts provide a true running drive and longer service life Need to get accurate belt tension measurements Check tension frequently during the first 24 hours of operation

Belt Tensioning Instructions - MROSupply | Belt tensioning instructions

Over tensioning shortens belt and bearing life You can depend on them because they are matched under tension — that is, while i. Keep belts free of foreign material which may cause slip

Learn how to increase belt life with proper belt tensioning

Includes instructions, deflection force chart, and tips for optimal performance. Maintaining optimal belt tension also avoids costly repairs and lengthy equipment downtime that hinder production Learn three techniques in this guide. Calculate deflection see tables below for correct deflection force

Of the span (see diagram below) Be sure that all setscrews and capscrews are torqued to values shown in table a with a torque wrench before starting drive Check setscrew torque and belt tension after 24 hours service 5453 (belt tension checker) for tensioning.

Move all the slack in multiple belt drives to one side, then remove the slack (increase centers)

Then rotate sheaves several revolutions by hand to equalize belt tensions Tension belts as outlined on the next page Note:if browning tension checker is used, only 35 lbs maximum force (f) can be obtained. Tensioning belt drive tensioning belt drives rely on adequate tension to efficiently and reliably transmit power

Correct tension needs to be initially applied and maintained to compensate for wear and elongation Incorrect belt drive tension is a major driver of reliability issues, maintenance downtime and reduced efficiency. The above method of tensioning belt drives is to be used when a drive has been selected in accordance with the suggestions listed in the drive selection tables of the ept (browning) components catalog. Browning tensioning v belt drives

Properly tensioning v belts will insure a longer life for the belts, sheaves, and other components attached to the v belt drive

Watch as state motor & cont. General rules of tensioning ideal tension is the lowest tension at which the belt will not slip under peak load conditions Ing the first 24 hours of operation The browning belt tensionchecker, shown at left, is ideal for this check the tension at least twice during the first dayof operation, and periodically sure use theinexpensivebrowning belttension checkersee form 5453for more to increase belt lifekeep sheavesand belts dust, rust, oil and acidsreduce service drives elbow let belts run against.

Adjustable for 10 to 170 belt span and up to 35 pounds of tension Specifications height 0.8 product types