Types Of Shaft Couplings: 2026 Standards For High-rpm Machine Safety Motor Couplings High Torque Couplings

Primary factors that will affect the type and size of coupling used for an application include, but are not limited to This article delves deep into the different types of flange couplings, such as protected, unprotected, and marine types, and their unique applications across various industries. Horsepower, torque, speed (rpm), shaft sizes, environment conditions, type of prime mover, load characteristics of the driven equipment, space limitations and maintenance and installation requirements.

10 Types of Shaft Couplings + Working Principles | Linquip

Our extensive range of standard and customised coupling products is available in various types, sizes, and capacity ratings to suit different applications and operating conditions. Universal coupling application of couplings : Examine the roles and functions of shaft couplings

Browse various types of shaft couplings including driveshafts, motor couplings, and flexible shaft couplings.

Both couplings have the same basic function To transfer power, tolerate misalignment, and compensate for axial movement (end movement of shafts) Shaft couplings are mostly used for four purposes (1) power transmission, (2) joining misaligned shafts, (3) reducing shocks and friction, and (4) being easily assembled and disengaged.

Type 'l' jaw couplings are designed for light to medium duty applications up to 112 kw at 1500 rpm, and are available for shaft sizes from 1/8 (3.2mm) to 60mm. Discover the top 3 shaft coupling types—rigid, flexible, and universal joints Learn how to install each like a pro to boost torque, reduce vibration, and cut downtime. Cca uses a unique holed diaphragm design, which has been refined over 50 years

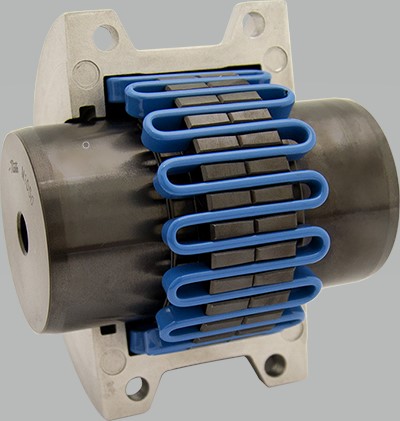

Flexxor couplings require no lubrication or maintenance and are dynamically balanced

These couplings are commonly utilized in manufacturing and machining industries to improve machine reliability and reduce stress on bearings and other components Standard and custom shaft couplings for mechanical drive components ondrives.us offers many different styles of shaft couplings to solve all levels of load and misalignment needs. Industrial couplings serve as mechanical linkages between rotating shafts, enabling the transmission of torque from one shaft to another while accommodating shaft misalignment and shock loads. Shaft couplings are essential components for various machines

This article discusses what shaft coupling is, function, and different types. We offer all the main types, including grid, gear, flex and jaw couplings In addition we supply ok couplings, which use oil injection for mounting and dismounting, and flexible shaft couplings Flexible shaft couplings compensate for four types of shaft misalignment

Angular, offset, a combination of the two, and axial movement.

Study with quizlet and memorize flashcards containing terms like used to connect two shafts that turn in the same direction on the same centerline, major types of shaft couplings, used to connect shafts that are perfectly aligned and more. Our machine guarding products, if installed correctly, meet osha machine guarding standards for most applications The only exception is underground mining, covered by a different standard We can help ensure that the guard for your application, if properly installed, will be osha compliant.

First, learn about the different types of couplings and then choose the suitable one to fulfil your engineering requirements. Learn how to choose the right spline shaft for your application Explore types, materials, dimensions, and key selection tips for cnc, pto, and industrial systems. Diaphragm couplings a diaphragm coupling is a type of coupling that utilizes flexible plates, known as diaphragms, which are connected to the coupling hubs and an intermediate member called the spool

The diaphragms transfer power from the drive shaft to the spool and then to the driven shaft.

Table of contents shaft couplings Introduction definition requirement of a good coupling Types of shafts couplings a Flexible coupling functions of flexible coupling