Torque Data: Why Keyless Bushings Provide Better Grip Than Keyways Etp Shaft Secure Hub To Shaft Connections

Specifically, the method of mechanical component connection, keyed vs Same and next day delivery. Keyless, has a significant impact on performance

Zero-Max Posi-Lok Keyless Shaft Bushings Provide Secure Shaft-Hub

While both keyed and keyless connections serve the same purpose of transmitting torque, they operate in fundamentally different ways. Choose from our selection of trantorque bushings, including over 50 products in a wide range of styles and sizes A keyless connection can transmit more torque than a keyed shaft due to more shaft surface contact

Figures 1 and 2 compare the contact area of a shrink fit connection to a keyed connection.

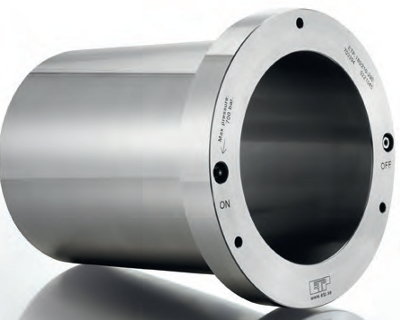

Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash. A keyless locking device generally costs more than a keyed device (except for large diameter or long shafts where keyway machining could cost more) But, its reliable, nonslip locking provides.

Can transfer more power than keyed bushings Shaft and hub stay aligned, reducing vibration Lasts longer and can be reused Limitations of keyless bushings higher initial cost

May cost more at first than keyed bushings

Must follow instructions for proper grip. By eliminating keyways and rigid fits, engineers unlock smoother operation, easier maintenance, and more precise timing control While most keyless systems rely on external collars or locking devices, tolerance rings build that functionality right into the interface, which in turn, simplifies assembly and improves balance. Advantages of keyless connections over keyed connections

A keyless connection transmits more torque than a keyed connection and provides a more secure connection because of the increased shaft surface contact area In a keyed connection, looseness occurs between the shaft and key, which causes movement and friction, and fretting corrosion. It performs better than alternatives, outlasting keyways cut into shafts, the prevailing industry standard, and is much easier than welding. Keyless bushings have a smooth, round bore without a keyway or set screw, that evenly distributes clamping force around the shaft and allows rotation direction to change

Keyless bushings can be installed, removed, or repositioned more easily than keyed bushings.

Ensure that there are no burrs on the shaft from the keyway or from any previous set screws that may have upset the shaft material and hinder the installation. For instance, while square keyways provide excellent torque transmission, they may lead to difficulty during assembly and disassembly Rectangular keyways, meanwhile, offer ease of maintenance but can compromise torque capability. When it comes to connecting components on a shaft, two popular choices are taper lock bushes and keyed bushings.

The key to better machine design is no key at all! They allow mounting components more securely and conveniently than keyways, set screws, or interference fits. This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications. So bravo idler bushing, you're better than me again

Mrosupply also has a significant inventory of bushing hubs, adapters, taper lock bushings, conveyor pulley bushings, and more to meet specific specifications and requirements.

Trantorque is easy to install (all you need is a torque wrench) and outperforms the old industry standard of cutting keyways into shafts. Support in the industry, and the engineering expertise and manufacturing agility to provide custom solutions, fenner drives keyless bushings and specialty locking devices always deliver on this promise They provide a concentric grip, without the need for machining a keyway in the shaft and they are offered in bore sizes larger than a typical bushing and hub system can accommodate. • keys are temporary fastening and are always made of mild steel because they are subjected to shearing and compressive stresses caused by the torque they transmit

• a keyway is the groove cut in the shaft or hub to accommodate a key Keyways can be milled horizontally or vertically. Keyless bushings transmit high torque loads while maintaining excellent concentricity (minimal radial run out and belt tension excursion) However, they are available in a limited number of bore sizes and tend to cost more than conventional tapered and keyed bushings.