Tolerance Data: Why Your 9 16 X 18 Tap Drill Size Must Be Exact And Chart

Tap tolerances and approximate limits unc/unf taps screw size and fractional threads are typically specified as one of three classes of fit. To drill holes for these taps, you'll need a drill bit that's slightly larger than the tap's thread size. The tap tolerance is positioned so that the tap cuts a thread correctly from the start

VARI-CRIMP SERIES - 3/8 INCH HOSE - WITH 9/16 X 18 THREAD SIZE - ORB

When the tap is used, it wears gradually, and will eventually be too small to cut a thread correctly, having become smaller than the lower tolerance of the go gauge. When the tap is used, it wears gradually and will eventually be too small to cut a thread correctly, having become smaller than the lower tolerance of the go gauge. The recommended practice for roll taps is to drill and ream the hole

The thread dimensions are formed by a combination of the tap and tap drill size

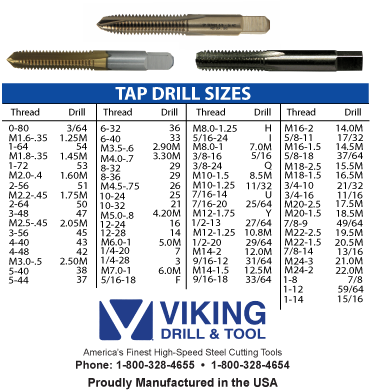

This recommendation chart is a starting point The tap hole size may need to be adjusted based on your specific tolerance, material, and hardness Converting between inch and metric will help finding drills of similar size. Ensure project success by choosing the right drill bit size for a 9/16 tap

Learn about the risks of incorrect sizing, such as thread stripping and shallow threads Avoid common mistakes like rushing the process and skipping safety measures for flawless threading results. In drilled components, this limit is defined by the drill tolerance Drill tolerance drill tolerance defines the permissible limits or the acceptable range of hole size variation, while still meeting the necessary functional fit for the drilled component.

You can learn more about thread depth in tapping here

To get the tap drill size in other depths, use our tap drill size calculator. The tap drill size depends on the thread type and diameter Using the right tap drill size helps you get the best core hole sizes, dimension,s and strong threads. When it comes to drilling the hole for a 9/16 tap, the drill bit size must be carefully selected to ensure a precise fit

While it may seem obvious, the drill bit size must be slightly larger than the tap size to accommodate the tap's cutting edges. Here, you'll find an extensive database of standard tapping drill sizes, alongside their corresponding clearance holes for metric and imperial units, tailored to facilitate the selection and use of screws and bolts in various applications. Discover the updated tap drill size chart with metric and imperial sizes Download the free printable pdf and master accurate hole sizing.

Basic tap size charts for strong holes and threads

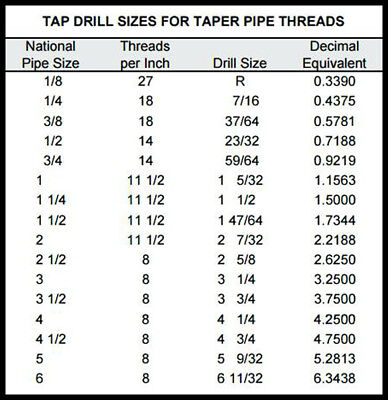

Learn about metric, unc/unf, and pipe thread standards, as well as tips for accurate drilling and tapping. Relation of tap pitch diameter to basic pitch diameter american tap manufacturers use a series of tap pitch diameter limits These limits feature a.0005 tolerance in tap sizes #0 thru 1 and a.001 or greater tolerance in tap sizes above 1 thru 1 1/2 diameter When choosing the correct drill and tap size for a 9/16 bolt, it's important to consider the material and application

This guide provides recommendations to help you make the right choice. Drill bit size chart guide with fractional, metric, number, and letter sizes Learn how to choose the right drill bit for wood, metal, and masonry. Speeds & feeds din standards thread mill cnc program generator tap drill calculator milling performance optimizer contact tech support

Tap drill size charts t he most common way to produce an internal female thread is to drill a hole smaller than the major diameter and then use a tap to produce the thread

This is usually referred to as a tapping drill for the size of thread that needs to be produced. This post will show how to utilize a thread tap size chart to get the right dimensions for your application Understanding how to determine the right tap size for machining, vehicle repair, or other technical operations promotes a good fit and material lifetime. Drilling is a process of producing a hole while tapping is a technique used to cut a thread inside a hole, so the drill bit and tapping tool are often used in sequential to fabricate cnc parts with thread holes

When it comes to the selection of drill bit sizes and tap sizes, there are standard drill and tap size chart for reference. Helicoil tapping chart, helicoil tap chart , helicoil tap size, helicoil tap , helicoil taps, helicoil insert,helicoil inserts,helicoil tapping tool, helicoil tool, helicoil tools,helicoil tool kit ,helicoil thread gauge Tap drill size calculator for ansi unified inch screw threads Calculations are done for thread sizes from 0.060 to 2 inch.

The tap tolerance is positioned so that the tap cuts a correct thread from the start