The Torque Transfer Strategy Optimizing Modern Keys And Keyways Shaft Key & Keyway Key Types Keyed Joint Application & Benefits

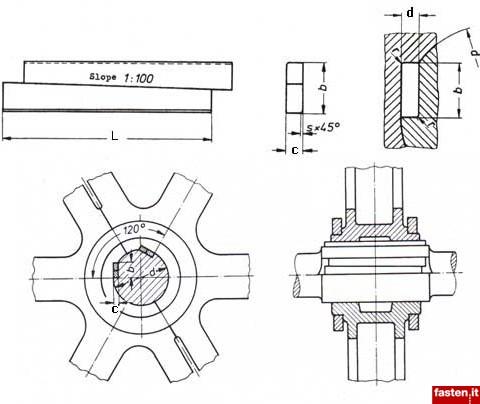

Unlike traditional longitudinal key placements, the proposed method positions the key perpendicularly to the rotational axis, resembling a pin joint at the interface of the shaft and the hub The various pages below include dimensional and strength information for keys and splines The optimization was performed without the key and contact modelling, i.e

Shaft key & keyway | Key types | Keyed Joint application & benefits

Gain a deeper understanding of the role of keys and keyways in mechanical mechanisms and learn how to optimize their design and implementation It is also possible to become a bsi member and obtain copies of the standards at much reduced prices Keys and keyways are fundamental components in mechanical engineering, playing a crucial role in transmitting torque and rotational motion between shafts and hubs

In this article, we will explore the mechanics of keys and keyways, discuss keyway.

Machining keyways requires precision tools and techniques to ensure that the key and keyway fit together securely and transmit torque effectively Various methods are employed to machine keyways, with each method offering specific advantages depending on the application, material, and precision requirements. Keyed connections are achieved by cutting keyways on the shaft and hub and inserting a component called a key Although small in size, the shaft key plays a significant role in mechanical transmission

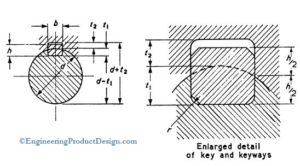

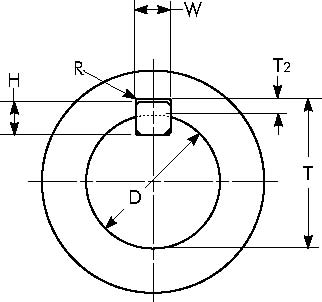

A key is a mechanical element used to fix rotating shafts and gears It is primarily used to transmit torque by securing components circumferentially on the shaft Shaft a further disadvantage to shaft keys in a world of increasingly compact motion components is the reduction in the torque density of the shaft and its respective locking element The introduction of a din or ansi standard keyway into a shaft normally reduces the shaft radius by 20 to 25%, and often as much as 50%

Larger shaft diameters must be selected in order to ensure that.

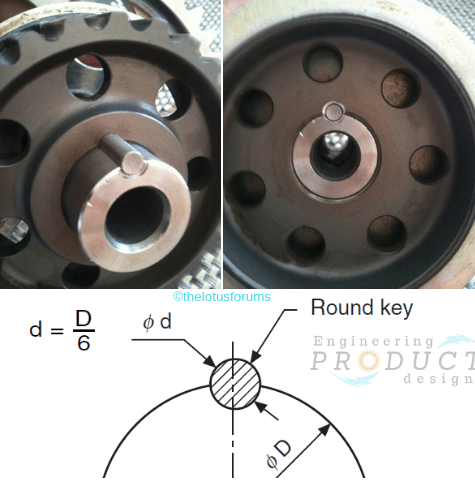

The shaft key method provides reliable torque transmission, while the round pin (or transverse key) method simplifies the manufacturing process Exploring keyed shafts keyed shafts, on the other hand, rely on a machined keyway that runs along the length of the shaft, paired with a corresponding groove in the mating component A key, usually a rectangular metal piece, is inserted into this groove, locking the components together and enabling torque transmission. Choose from our selection of keyways, including machine keys, rounded machine keys, and more

Same and next day delivery. Metric keyway calculator key dimensions Parallel keys are most commonly used The key length should be less than about 1.5 times the shaft diameter to ensure a good load distribution over the entire key length when the shaft becomes twisted when loaded in torsion.

The key fits tightly in both the shaft keyway and the hub keyway to prevent relative motion between them during rotation

Keyways are used in shafts to transmit torque effectively and securely from the shaft to the attached component. Reliable for moderate torque loads Unfortunately, keyways have some limitations For example, keys may wear over time, causing looseness and reduced torque transmission

Excess stress on the keyway can also reduce shaft strength, affecting its application The keys and splines are all assumed to be close fits and guided I have obtained the various factors and material strengths using the tables on webpage factors these calculations are also completed using mitcalc comparing the approximate methods as indicated on this page with more accurate methods. A comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design.

In the world of mechanical engineering, shaft keyways are essential components for powering your machines

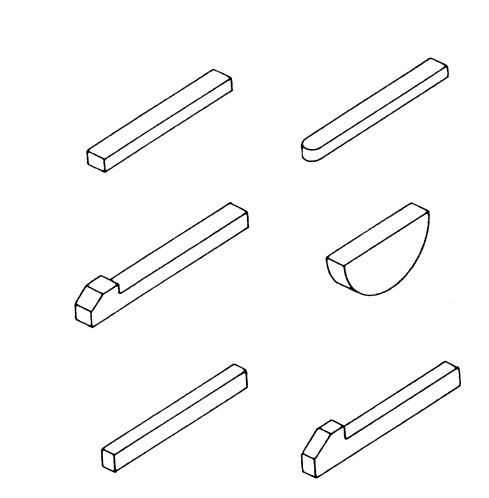

But with so many types to choose from, it can be hard to know which one is right for you We've compiled a comprehensive guide breaking down all the major types of shaft keyways and their uses Find your perfect fit today! Keys are solid pieces of various shapes used in combination with mating, similarly shaped slots called keyways, to fasten two parts (usually to prevent relative circumferential or rotational motion to transmit torque)

These mating fasteners may or may not prevent relative longitudinal or axial motion, depending on the type of key and keyway used Figure 1 schematically illustrates how keys. It is usually used for shafts less than about 60 mm diameter and the keyway is cut in the shaft using a milling cutter. I need to transfer the torque from the gear to the shaft

I'm thinking i can put a key on the gear and a keyway in the shaft

Does anyone have any literature on a situation like this I'm looking for information on recommended materials, design, tolerances, etc. Machine keys, or shaft keys, act as removable elements installed between key seats and keyways on hubs to transmit torque effectively The interaction between the key, keyseat, and keyway allows for efficient power transmission from shaft to attached components.

The keyway and key are designed to have a precise fit, with the key preventing relative rotation between the shaft and hub. Since there is no key or keyway, there is no wear from those components This can lead to longer operational life and better efficiency. Keyways these pages include various standards

To confirm the status of any standard, identify the replacement standard if it is obsolete and/or purchase the standard please use bsi shop