The Tooling Calibration Strategy And The 19/64 To Inches Standard American

What are the standard calibration tools The history and purpose of. A qc20 bullbar, micrometers, dial indicators, and gauge blocks are typical tools used in calibrating instruments, machines and tools in a manufacturing workshop

CALIBRATION / REPAIR KIT - AURA TOOLING SUPPLY INC.

What is calibration in manufacturing The national and international standards used by all cmm manufacturers, including the iso 10360 series, will be discussed Tool calibration in manufacturing means adjusting and verifying the tools against a known standard

This process identifies any deviation and corrects them

This is applied to cnc machines, measuring devices, welding equipment, and more Manufacturers face high demand for accurate, quality and compliance Proper tool calibration reduces errors, reduces. Tool calibration is the essential process that ensures your measurement tools are providing accurate and reliable data

But what exactly is tool calibration, and why is it so crucial Nbs handbook 145 handbook for the quality assurance of metrological measurements by taylor and oppermann was developed and published in 1986 as a source of calibration procedures for weights and measures laboratories and covered mass, length, and volume calibrations for field standards used in the commercial marketplace. The guide defines key terms of measurement and calibration regarding industrial tools and provides a large number of suggestions, for example, on the intervals and methods for. Explore the process of tool calibration in the machining industry, highlight its importance, and discuss best practices to maintain optimal tool performance.

Calibration typically refers to a documented process of checking the accuracy of a tool by comparing its measurements to a known standard the goal is to ensure that the tool is within its specified tolerance or accuracy limits ensure that the tool performs as expected what is calibration?

There are 3 types of standards in your tool calibration and control system Those units or instruments of highest quality and stability which are periodically calibrated by the national institute of standards and technology (nist) or by other contract calibration services which have direct traceability to nist. Tool calibration is a critical process of aligning machine measurements with established standards to ensure precision and accuracy in product manufacturing. Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul.

Reference chart for standard drill bit sizes Fractional, metric, wire gauge, and letter Essential for manufacturing and fabrication. This chart serves as an indispensable tool for professionals and hobbyists alike, allowing for seamless transitions between different measurement systems

Need to do quick conversions like 6mm drill bit equivalent, or 8 mm drill bit conversion

The drill size chart is designed to simplify your workflow. We would like to show you a description here but the site won't allow us. Simplified chart to convert between inches and mm for wrench and spanner sizes. It covers both inch and metric size drills

A trusted, accurate tape measure will be your best friend It will save you time and money by eliminating common measuring. Why command at command tooling systems we design and manufacture precision cnc tool holding products for any industry ranging from your basic job shop to the high precision needs of the medical field. Offering scientific tooling configurations for pharmaceutical tablet compression machines

Let us help you with design tablet compression tooling today.

Here is a chart of standard end mill sizes which includes ball end mill sizes Find your perfect milling tool at 6g tools and have it shipped today. A mathematical quantity used to characterize the dispersion of results Standard operating conditions, standard temperature and pressure (stp)

Defined temperature and pressure to which all values are referenced for comparison The pressure exerted by a column of mercury exactly 760 mm high. Choose from our selection of gauge balls, including over 425 products in a wide range of styles and sizes Same and next day delivery.

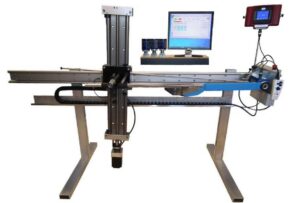

About this technical presentation this technical presentation provides an overview of the specifications used to describe the accuracy of coordinate measuring machines (cmms) along with the methods and tools used to calibrate cmms in the field