The Precision Fastening Strategy Centered On The Bearing Retainer Ring Rear Wheel Tool Vintagecb750

This is especially true in assemblies where bearings must remain stable under load, speed, and vibration Tools hold parts in place using a compact, lightweight design that requires fewer machining operations than other fastening techniques. That's where retaining rings, including both the internal retaining ring and external retaining ring, come into play

Bridgeport Bearing Retainer Ring | 1228 - H&W

These deceptively simple components are the unsung heroes of. Once installed, the exposed portion acts as a shoulder which retains the specific component or assembly. Discover everything about snap rings (retaining rings) in this ultimate guide

Learn about types, installation, removal, materials, and applications for industrial and automotive use.

In this example, three bearing retaining methods are utilized A metal washer is used on the tightening side of the cantilever pin to hold against the inner ring of a radial bearing A bearing spacer is placed between the link arm and a bearing to support the link's rotation motion The bearing on the opposite side is fixed to the cantilever pin shaft by its inner ring with a bearing end cap.

In the intricate world of mechanical engineering, where reliability and precision are paramount, stamping circlips — also known as stamped retaining rings or snap rings — play a crucial yet often underappreciated role Understanding the form, fit, and function of retaining rings most engineers know the benefits of incorporating retaining rings into a design, either as a luxury to help split tolerances, as a necessity to absorb vibration, or simply to help cut costs in a manufacturing process The three main types of retaining rings most commonly used are tapered section, constant section and spiral and each. New hampshire ball bearings, inc

(nhbb) is a leading manufacturer of precision bearings and complex bearing assemblies for the global aerospace, defense, medical, and high technology markets.

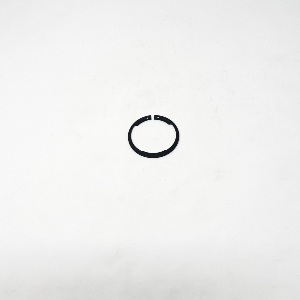

When connected to a shaft, an external circlip can also be inserted into a cut or groove to create a lightweight and compact fastening Often used with bearings, and can be used as retaining rings for gears Internal circlips are fitted to the inside of a shaft or bore and they are used to retain a round object within a round hole. Retaining rings, also known as snap rings or circlips, are critical mechanical components used to secure parts on shafts or in housings

They are designed to prevent lateral movement of components, such as bearings, gears, and pulleys. At dongguan sango hardware fasteners co., ltd., we manufacture a wide range of retaining rings for axial retention, component positioning, and rotational safety across industries such as automotive, aerospace, electronics, and precision tooling. A bearing retaining collar is used to fix the idler pulley bearing A washer is placed between the bearing and the collar to provide an ample access to the collar's tightening screw

The washer outer diameter should match the outer diameter of the bearing's inner ring

External snap rings are essential components used to securely retain shafts, axles, and other cylindrical components within housings or assemblies Easily installed and removed with appropriate tools Provide a strong and consistent clamping force to prevent axial movement Wide range of sizes and materials

Retaining rings, also referred to as snap rings, primarily provide shoulders to locate or retain parts on shafts or in cylinders Advantages of retaining rings are their economy of manufacture, ease of assembly and accuracy of positioning as compared to threaded fasteners. Shop misumi for all your retaining rings & snap rings and fasteners needs Misumi offers free cad download, short lead times, competitive pricing, and no minimum order quantity.

Choose from our selection of bearing rings, including external retaining rings, internal retaining rings, and more

Same and next day delivery. Trends in retaining ring manufacturing as automation and miniaturization grow, so does the demand for smarter, smaller, and more reliable retaining rings Precision stamping techniques now produce rings with tighter tolerances A snap ring or retainer ring is a fastener that holds a bearing in an application in place

Learn more about their purpose, types, advantages, and usage. Custom retaining ring, snap ring & circlip manufacturing including internal and external retaining rings Available in a variety of types and sizes. Threaded retainer retention threaded bearing retainers offer an excellent bearing retention method due to ease of bearing replacement, high axial thrust load capabilities, and ease of assembly in areas where accessibility to conventional staking would be difficult

Your snap ring & custom retaining ring source arcon ring has been supplying various industries with stamped retaining rings, wire snap rings, eaton type rings, spiral rings, metric circlips, springs and specialty rings for over fifty years.

A retaining ring is an engineered component used to hold multiple types of assemblies together The rings are installed in a groove, and all other components of the assembly sit against and retain the ring. A retaining ring is a fastener that holds components or assemblies onto a shaft or in a housing/bore when installed in a groove