The Precision Engineering Strategy Required For Custom Key Way Size 1st Edition Download

Shaft key and keyway work together to create a robust interlocking mechanism Our push, pull, one pass, production and keyway broaches with bushings reflect our heritage of innovation and expertise and reliability. How to design an accurate keyway

Precision Design & Engineering - Crunchbase Company Profile & Funding

This guide provides a comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design In manufacturing, especially in precision engineering, requirements are set based on the tolerances that are acceptable for product functionality. What are keys and keyways in engineering, and how do they work

In mechanical engineering, a key is a crucial machine element that connects a.

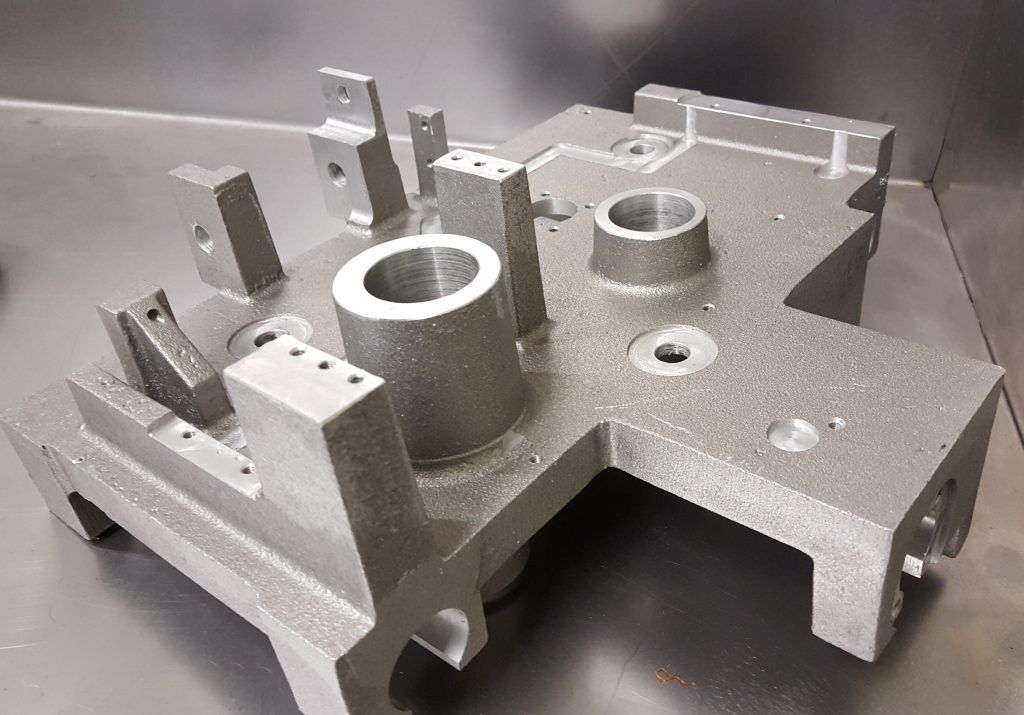

Machining keyways requires precision tools and techniques to ensure that the key and keyway fit together securely and transmit torque effectively Various methods are employed to machine keyways, with each method offering specific advantages depending on the application, material, and precision requirements. Welcome to the definitive guide on keyway machining, where precision meets performance Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey.

Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. Useful engineering data a collection of useful data for engineering applications limits and fits the system of limits and fits is useful for determining tolerances of components that need to have a relationship or function with one another For example, clearances fits ranging from loose to precision sliding fits. Whether you are in mechanical engineering, manufacturing, or repair work, knowing the correct keyway size chart is essential for ensuring proper fits, safety, and durability of mechanical assemblies.

Precision machined products association's mission is to progressively lead members to sustainable success with reliable and relevant information, resources, advocacy, and networking opportunities

Shaft key selection and keyway design should consider key types, correct fit, key material, shaft material, load, fatigue & safety factors To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint. Standard metric keys & keyways for metric bores with one key • couplings (page 2 of 2) all types Precision engineering is a specialized discipline focused on designing and manufacturing highly accurate and reliable components and systems, often crucial in industries like aerospace, robotics, and electronics.

In this blog, we'll explore the factors to consider when selecting a keyway broach and how to make the best choice for your precision machining requirements. Complete guide to shaft keys covering the motor key types, dimension formulas, strength calculations, material selection, and practical case studies for reliable torque transmission. Enhance productivity and achieve exceptional results in your projects. Ryh jeng engineering & trading is the pioneer company in gear manufacturing in singapore

Products include gears, sprocket, rack and pinion, hydraulic cylinders

Services include cnc lathe, cnc slotter, milling and welding. The dumont and hassay savage companies have been designing and manufacturing precision broaches for decades, and these broaches are recognized all over the world for their quality, durability and engineering detail The size and shape of your workpiece will dictate the appropriate machine size and capabilities High volume production often favors cnc machining or broaching for speed and efficiency

For very tight tolerances, cnc machining centers often excel. This article explains the essentials of end milling in modern manufacturing, covering its process, types, and unique applications. Aria allows customers to customize injection molding, cnc machining and sheet metal parts to their specific requirements. Custom keyway and broaching services custom keyway and broaching services as a provider of keyway and broaching services, precision gears, inc

Offers an efficient way to machine keyways and internal splines

Delve into keyway machining, its methods, and common issues, ensuring high precision for effective power transmission. Find the right metric set screw size for your keyways Learn about the importance of precise measurements and how to achieve the perfect fit. One of the lowest cost methods for cutting an internal keyway while maintaining excellent precision

The use of replaceable inserts eliminates the need for expensive custom broaches or specialized machines.