The Misalignment Strategy Behind Modern Types Of Shaft Couplings 10 + Working Principles Linquip

Items to consider when choosing shaft misalignment couplings Advantages of bushed pin flexible coupling it can tolerate slight misalignment In designing these systems, engineers idealize perfect alignment of shafts and rotating components, but out in the real world, building a machine in which adjacent shaft ends.

Types of misalignment shaft | Download Scientific Diagram

Coupling for misaligned shafts introduction to shaft couplings shaft couplings play a pivotal role in mechanical engineering, allowing for the efficient transmission of power between two rotating shafts Both the flanges are connected with rubber bush in between, which provides resistance to shocks and slight misalignment This article delves into the intricacies of couplings designed specifically for misaligned shafts

Types of misalignment misalignment in shafts can be categorized into angular, parallel, and.

A complete guide on coupling misalignment—causes, detection methods, and prevention techniques to protect bearings, seals, and rotating equipment. Discover how shaft couplings transmit torque, handle misalignment, and protect machinery This simple guide covers coupling types, alignment tips, and maintenance best practices. Although flexible couplings are preferable because they compensate for part of the misalignment, there are generally accepted standards for shaft misalignment with various types of coupling

Premature bearing, seal, shaft or coupling failure High housing temperature close to the bearings or high oil discharge temperature. Studies also show that significant energy losses can occur when particular types of shaft couplings are misaligned due to the added side loads on the connected shafts Old methods of alignment would use things like, piano wire, ruler, line of sight or dial indicators.

As the misalignment increases, the transmissible torque and life expectancy of the coupling reduce exponentially

Therefore, understanding the nature and origins of misalignment is important to you as a design engineer The main types of misalignment are angular, radial, and axial displacement. Pieces of rotating equipment are connected through a shaft coupling, every effort should be minimize coupling and shaft misalignment Proper alignment will reduce bearing, shaft and failures, bearing and coupling temperature, vibration, and energy consumption

In addition, will extend equipment life between planned maintenance intervals Introduction couplings play a pivotal role in connecting rotating shafts and transferring power efficiently within machinery One critical factor that can impact the performance and longevity of couplings is axial misalignment In this article, we'll delve into the intricacies of how couplings handle axial misalignment and explore the various types and solutions available

Coupling for misaligned shafts coupling for misaligned shafts introduction to shaft couplings shaft couplings play a pivotal role in mechanical engineering, allowing for the efficient transmission of power between two rotating shafts

Types of misalignment misalignment in shafts can be. Discover the different types of shaft couplings, why they fail, and how to choose the right one for your machinery Get expert tips to avoid costly breakdowns. Examine the roles and functions of shaft couplings

Browse various types of shaft couplings including driveshafts, motor couplings, and flexible shaft couplings. It is always necessary to take into account the size, geometry, or operating temperature of a given machine How much vibration and efficiency loss will result from the misalignment of shaft centers depends on shaft speed and coupling type Acceptable alignment tolerances are thus a function of shaft speed and coupling geometry.

A small misalignment or vibration in parts can lead to downtime and equipment damage in industrial machinery

Couplings solve these problems by absorbing shocks, managing misalignments, and transmitting power efficiently In this blog post, we will explore the top 10 types of couplings and important factors to consider for selection of couplings. Introduction to shaft couplings shaft couplings are indispensable components in mechanical systems, ensuring the smooth transmission of power between two rotating shafts They come in various designs to accommodate different operational requirements and environmental conditions.

What are the two general types of shaft couplings There are two general types of shaft couplings Rigid couplings and flexible couplings Rigid couplings provide a fixed connection between two shafts, ensuring precise alignment and minimal play, making them suitable for applications with exacting alignment requirements.

Diaphragm couplings a diaphragm coupling is a type of coupling that utilizes flexible plates, known as diaphragms, which are connected to the coupling hubs and an intermediate member called the spool

The diaphragms transfer power from the drive shaft to the spool and then to the driven shaft. Primary factors that will affect the type and size of coupling used for an application include, but are not limited to Horsepower, torque, speed (rpm), shaft sizes, environment conditions, type of prime mover, load characteristics of the driven equipment, space limitations and maintenance and installation requirements. Drive shaft coupling types introduction in the world of mechanical engineering, drive shaft couplings play a crucial role in transferring torque and rotational motion between two shafts

There are various types of drive shaft couplings, each designed to suit specific application requirements In this article, we will explore different drive shaft coupling types and delve into their unique. A basic introduction to misalignment in flexible couplings Let's say you want to power a pump

This means at the very least you will need a pump, a motor, and a means of transmitting rotational power

Generally speaking, the power from the motor will rotate the shaft, which transmits power through the coupling to the […] Understanding shaft coupling types choosing the right fit with belon gear in modern mechanical systems shaft couplings play a critical role in transmitting torque between rotating shafts while accommodating misalignments, absorbing vibrations, and protecting components from overload Couplings are mechanical elements that connect two drive elements, allowing the motion from one to the other Shafts are commonly used as drive components

So, a shaft coupling is a mechanical feature that connects two shafts to transfer torque from one end to the other while accepting misalignment Shaft couplings add mechanical stability, allowing for shaft misalignment tolerability In the past, identifying and fixing the different types of shaft misalignment required a highly experienced expert Today, more and more organizations are using modern laser shaft alignment tools to quickly discover misalignments and fix them easily

The causes of shaft misalignment

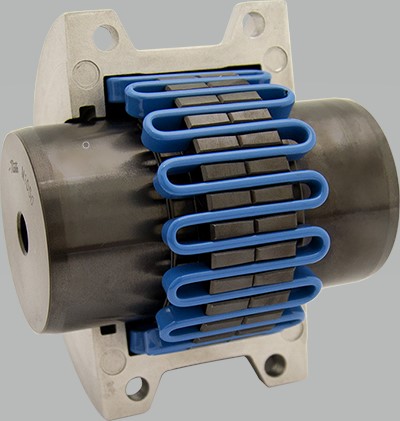

Bushed pin flexible coupling as the name suggests it is a type of flexible coupling It consists two flanges mounted each on input and output shaft